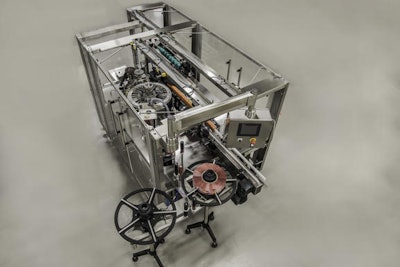

During ProFood Tech 2019, LANGGUTH debuted the concept of its rollLAN 494, an inline roll-fed hot melt labeler capable of operating with thin film oriented polypropylene (OPP) labels. With speeds above 700 bpm, the rollLAN delivers continuous output through the use of servo-controlled container handling and large slow turning vacuum drum. Consistent with LANGGUTH’s cold glue and pressure sensitive labeler designs, the rollLAN is built to perform for decades of multi-shift operation, according to the company.

To expand LANGGUTH’s product offering to its customers, the OEM developed the rollLAN roll-fed portfolio for use with carbonated and still beverage and home care products like aerosol. Further complementing LANGGUTH’s hotLAN cut and stack hot melt labelers, the rollLAN roll-fed addition now allows LANGGUTH to satisfy most hot melt adhesive applications.

During ProFood Tech 2019, LANGGUTH debuted the concept of its rollLAN 494, an inline roll-fed hot melt labeler capable of operating with thin film oriented polypropylene (OPP) labels. With speeds above 700 bpm, the rollLAN delivers continuous output through the use of servo-controlled container handling and large slow turning vacuum drum. Consistent with LANGGUTH’s cold glue and pressure sensitive labeler designs, the rollLAN is built to perform for decades of multi-shift operation, according to the company.

To expand LANGGUTH’s product offering to its customers, the OEM developed the rollLAN roll-fed portfolio for use with carbonated and still beverage and home care products like aerosol. Further complementing LANGGUTH’s hotLAN cut and stack hot melt labelers, the rollLAN roll-fed addition now allows LANGGUTH to satisfy most hot melt adhesive applications.