With apologies to Sir Isaac Newton, dropping is not good for apples. Or for apple slices. “That leads to increased bruising and reduced shelf life,” points out Tony Freytag, general manager at apple processor Crunch Pak LLC. Having as short a drop as possible during bagging was a primary requirement when Crunch Pak looked to automate its sliced apple operations in September 2001.

“Short and squatty is better,” sums Freytag, who kept eyes peeled for appropriate bagging equipment. “And the longer the drop and the longer to get from point A to point B, the slower the machinery runs.”

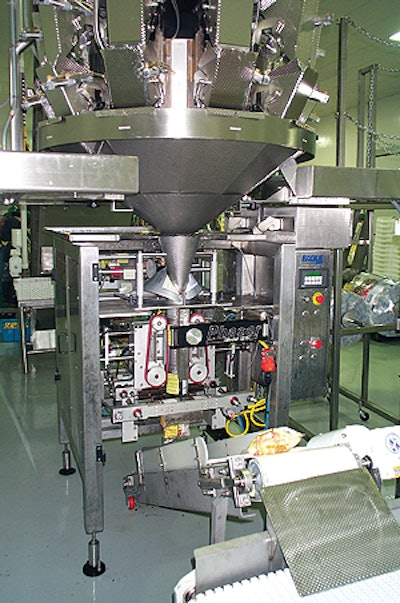

In short, the company installed low-profile EaglePack (Oakland, CA) Phaser® vertical form/ fill/seal baggers at its headquarters location in Wenatchee, WA, at the core of the state’s apple growing region. Low profile refers to the entire integrated system, including the combination weighers. The first was operational in September 2001, the second in early 2002.

“Some bagging equipment I’ve seen is nearly 20 feet tall,” continues Freytag. Including the weigh scales, Crunch Pak’s are considerable shorter. Thus, the quality of Crunch Pak’s product soars because these Eagles don’t, at least heightwise. Other undisclosed modifications were made to reduce bruising of the slices.

“Product integrity is our highest priority,” says Freytag. “It doesn’t matter if you can produce 200 bags per minute if the product ends up looking like apple sauce.” Bag sizes are 2 oz (which run the fastest) and 6 oz, and 1 lb and 3 lb (which run the slowest).

The machines are capable of 60 cycles/min, although Crunch Pak declines to say how fast they run theirs. For Packaging World’s visit, zippered 1-lb packs were produced. The 3-lb size is a bulk pack for grocery stores that repackage the slices into party packs and snack trays. The 6-oz size includes a cup of caramel sauce for dipping. Crunch Pak provides two varieties of each size, either tart or sweet.

The automatic bagging is a higher-speed, lower-cost improvement over manual packing using preformed bags that was done prior to last September.

When the company relocated and expanded its production operations in February 2002 into a larger, more modern facility nearby owned by its parent company, Dovex Fruit Co., Crunch Pak installed a second EaglePack bagger next to the first.

“Our new layout was designed by us,” says Freytag. “There were no blueprints for this.” One large area kept chilled was designated for processing and bagging. “It’s not a sterile area, but has a very high level of cleanliness,” he says. Operators entering the area must be properly garbed and step through a sanitizing bath.

Whole apples that have been scrubbed are conveyed into the room; when they are conveyed back out, they have been sliced and bagged.

The upgrades have raised the company’s output. “We’ve had processing upgrades, but the big difference has been the EaglePack machines,” says Freytag. The move to automatic bagging reduced the company’s labor costs.

The steps leading to the baggers are also crucial, and start with a very high grade of inbound raw fruit. “Otherwise it doesn’t matter what we do to it, it’s still not going to last as long or taste as good as we want,” notes Freytag.

Uniformity critical

Inside the room and ahead of bagging, the apples are scrubbed and sliced. The slices are treated with an all-natural vitamin-mineral solution that prevents browning. “How we connect the various operations and the specific conditions, that’s the science,” says Freytag. “We guard that very carefully.”

Immediately upstream of bagging, human sorters check for defective slices. Uniformity is crucial for its operations, according to operations manager Todd Danko.

The scale programming automatically selects buckets most closely matching the target weight; those buckets then direct their contents down the filling tube.

The longitudinal seal is made in intermittent motion as the seal bar presses against the forming tube (for more film details, see sidebar p.71).

The seal bar seals the bag bottom, indexes, and then seals the bag top. It seals the bag top of one bag and seals the bottom of the next as it cuts between the two seals.

Bags are discharged onto an inclined conveyor before they transfer onto a conveyor that takes the bags from the isolated area and into the warehouse for secondary packaging.

The pack’s 21-day shelf life, contact coded by a thermal-transfer unit on the film unwind, allows the apple slices to be sold to stores across the United States.

Danko says size changeovers take 12 minutes and require adjustment of the registration photoeyes, film contact coder, forming tube, and settings on the machinery panels. Film roll changes, needed for a change from tart to sweet varieties, take five minutes.

The company was selected to provide its apple slices for the Winter Olympics in Salt Lake City (see p. 13).

With business continuing to grow, Crunch Pak installed in mid-September a third EaglePack Phaser bagger.

See sidebar to this article: Bag film: A 'touchy' subject

See sidebar to this article: Bagged apple slices reach for the goldn