Cole Haan, a unit of Nike, Inc., is based in Yarmouth, ME, and is a major brand of casual luxury footwear, handbags and other products. The company works with factories all over the world, including Mexico, China, India, England, Italy and Brazil. “And we have multiple factory locations within most of those countries,” points out Irene Bellfy, Cole Haan’s director of production, distribution and customer service.

The company also operates a design studio in New York, and its sole U. S. distribution center is in Greenland, NH, where Steve Berube is director of distribution and customer service. It’s at the distribution center where the company most benefits from the use of InfoChain Express (ICE). Since 1999, Cole Haan has employed enterprise resource planning software supplied by SAP. So when the company sought to streamline its electronics communications with its manufacturing locations, it had two possible routes.

“We could have had all the factories we buy from spend the time, money and training to link directly with our SAP software to receive purchase orders and transmit shipping notices,” Bellfy says. “Or we could—as we did—use the InfoChain Express system to serve as the middleware between the factories and our SAP system.”

Sending solid information

The key to the system was creating the right software that would drive hardware and software at Greenland and at each manufacturing location worldwide. The company wanted to modernize its inventory system at Greenland, and it wanted to standardize its supplier factories into providing information and scannable labels that would work at the factory, at the DC, and at the various retailers it sells to and through to automate the processing of information on orders.

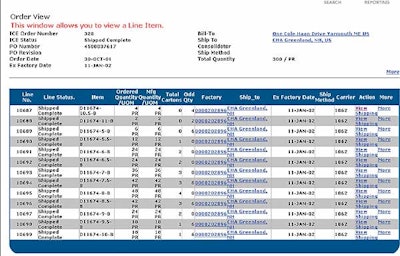

Using Avery Dennison’s secure network—in this case as an application service provider (ASP)—Cole Haan transmits purchase orders to the factories that are now client-based so those factories can produce carton packing plans that will help eliminate work at the Greenland DC. Before the order is shipped in to Greenland, the factory uses the same ICE system to transmit an Advanced Shipping Notice (ASN) to the DC.

At the DC, ICE software extracts the information from the ASN so that it can quickly update its electronic inventory when the order is received there. This electronic updating—along with some label changes—helps the DC eliminate some handling steps.

“From an operations standpoint,” Berube explains, “the new process takes several steps out of handling process. We handle two types of receipts, product that arrives and goes into general inventory or product that arrives prepackaged for the end customer, which we call cross-dock orders.

“Before we started using ICE, we’d have product coming in the door, and we’d have to receive it, store it, replenish it, pick it, and ship it. Thanks to the new software, when processing cross-dock orders, all we do is receive it and ship it. So we’ve cut out all the middle—and the most expensive—steps here at the DC. For general inventory stock, ICE helped us streamline the process by allowing us to only scan the carton’s UCC128 label, instead of all individual pair boxes.”

The primary advantage is that the DC no longer has to open up the shipping cartons to ensure that it contains all the products destined for a customer or for inventory. In the past, upon receipt of a shipment, workers had to open each carton to scan the UPC code on the individual box.

“Now we just scan the outer label on the shipping carton, and the software matches up the information with the ASN we received before the box arrived,” Berube explains. “We can process the data much faster, and we’ve essentially doubled the throughput here at the DC.”

Developing the protocol

The key to the system, other than the software, was in developing identical label information at all locations around the globe. Not only is Cole Haan’s manufacturing worldwide, but it also ships its products internationally as well.

When it began to work with the ICE program, Cole Haan had to develop totally new label standards using UCC 128 protocols. It also redesigned address labels, and the location label needed for internal use at the DC.

“It took some time to do this, but it wasn’t a difficult project,” Bellfy states. “The distribution center was already doing a lot of that work for our outbound shipments to customers. So we were able to piggyback off that effort that had been done under the implementation of our SAP program.”

She reports that one of Cole Haan’s Information Technology specialists was vital to get the ICE software integrated with that of SAP; another IT member was knowledgeable about the software at the DC, so he was able to make sure the ICE program coordinated well there.

There was some investment on the part of the factories. Each was required to buy some equipment like scanners and label printers. Now, Bellfy says, most of Cole Haan’s factories are on board with this program, and all factories will be operating on the newest version of ICE when the upgrade implementation is completed in the beginning of 2005. Over the two years since it began using ICE, the company has done some “tweaking” of the pack plans at the factories to make them more user-friendly.

“Right now, we’re going through an upgrade of the program to the latest version of InfoChain Express,” she says. “It’s going to be much easier for the factories, we feel, because it’s going to be client-based at their facility. We expect to see better usability at the factory level.”

All business in English

Even though the factories are located in many countries where English isn’t spoken, all software for ICE is created in English. “For the most part, the factories we deal with have people who speak English,” says Bellfy. The factories are A-level, she adds, and English is the language of business.

“We do some business with some small artisan factories in Italy, for example, where it’s more challenging for them to use this software in English.” However, the real key to factory adoption of the program has been the Avery Dennison teams around the world. “The company has training and implementation teams all around the world,” says Bellfy. “These teams do a lot of the upfront survey work, identify what’s needed for implementation, and then conduct training on-site. This technical back-up has been very helpful.”

Bellfy acknowledges that employee turnover at factories, especially those in India and China, has been an issue at times, and the training provided by Avery Dennison has been important. In fact, Cole Haan is now developing a “train the trainer” program at some factories.

Low-cost implementation

While the factories involved had some modest expenditures to be able to participate in ICE with Cole Haan, Bellfy says her company’s investment was modest. “Yes, there was a lot of time and effort devoted to implementation of this project,” she says, “but not a lot of dollars in investment.”

Plus she points out that Cole Haan has not identified any cost increases that specifically relate to the use of the ICE system. At the Greenland DC, Berube says he can calculate the savings it has created.

“This initiative has allowed us to reduce our handling costs significantly,” Berube says. “Since we eliminated opening up individual shoe boxes, ICE has resulted in a 12% decrease in our distribution center labor costs. We receive over four million pair annually, so the savings add up quickly. The order picking cost was our biggest expenditure, and this electronic data system totally eliminates that for cross-dock orders.”

The DC ships orders to company-owned stores and to customers like Saks, Nordstrom, Bloomingdales, and Neiman-Marcus, as well as to small, exclusive apparel shops. Most customers are in the United States, Bellfy says, but international sales are growing. In fact, Cole Haan’s business in Japan is growing rapidly, but products for that market don’t go through the Greenland DC. The product destined for Japan is still handled through ICE and SAP, Bellfy explains.

“Operationally,” says Berube, “we started to see payback when we received the first shipment using this new process. The benefits at our distribution center were almost immediate.”