Arla Foods’ new dairy plant in England provides ample evidence that necessity is indeed the mother of invention. Head of engineering Soeren Vonsild describes Arla’s necessity this way.

“In this dairy we process milk for five supermarkets, each with its own label. We make four sizes: one-, two-, four-, and six-pint. And we process skimmed, semi-skimed, and whole milk. That comes to 55 stock-keeping units, and we go through that sequence every day. To minimize changeover time, we needed a whole new level of flexibility. We had to come up with a new way to manage things here.”

The “new way” Arla came up with is a superb example of process-to-package integration. The plant, located near Leeds in England, houses four identical packaging lines. Running commercially since August of 2004, they draw freshly blown high-density polyethylene bottles from silos and freshly processed milk from processing tanks with minimal operator involvement. Production is monitored and managed by a newly developed automated order system from Syskron called Line Management System. No longer does a shift manager deploy a team of operators to stop and start machines according to a production plan. The stopping and starting are done automatically, leaving operators responsible for changing label reels and replenishing the cap hopper.

“We transmit production orders from the ERP down to processing and packaging machinery and collect data from those machines so that it can be sent back up to the ERP,” says Vonsild. “It makes our business one single unit.”

Each packaging line has the same equipment:

• a Contiform roll-fed labeler from Krones

• a Krones rotary electronic weigh filler

• a Zalkin capper

• an Enercon induction sealer

• two trolley packers from Elopak

Filled trolleys holding a hundred or so bottles (depending on bottle size) are wheeled into delivery trucks and later right into the store’s refrigerated case that’s accessed by consumers. The trolleys nest for easy return to Arla.

Other essential equipment tied into the network includes milk processing equipment from Tetra Pak and eight blow molding systems owned and operated on-site by Logoplaste. Running continuously, the Logoplaste machines maintain a steady supply of bottles so that the filling lines can automatically draw bottles via a conveyor system whenever they’re needed.

“Each line might do up to 30 changeovers every day,” adds Vonsild. “If a changeover took 10 minutes, that would be 300 minutes of downtime per day. We can’t afford that. So, through the Line Management System, we’ve integrated everything in such a way that changeovers are managed automatically.”

Batch approach

Production orders flow through the plant in batches. For example, a supermarket might need a batch of 10ꯠ 4-pint skimmed-milk bottles, while nine other supermarkets each need the same milk in the same bottle but in different quantities. All 10 of these batch orders flow from the ERP system to the plant floor in such a way that when it’s time to switch from one retailer to another, the new label is all queued up and ready to be spliced. With a minute’s production time lost, the change is made.

Few, if any, operators are stationed on the actual filling floor. Their place is above on the second floor, where labelers and cap hoppers sit. They check an HMI screen to see what batch the ERP system has scheduled and what they have to do to prepare for it. One thing they never have to worry about is introducing a new bottle size to a line, since each line is dedicated to a single size. What does change from batch to batch is the fat content of the milk being filled, the label being applied, the ink-jet coding that goes on the label, and the bottle closure (a different color for skimmed, semi-skimmed, and whole milk). Based on what the operators see on their HMI screens, they mount the proper label roll on a splicing unit and confirm it has been mounted. They also fill a cap hopper with the appropriate caps. Again, they confirm at the HMI screen that this action has taken place. Without these confirmations, the system won’t proceed to the next batch order.

As the changeover to a new label is made and bottles with label B now proceed to the filler, as soon as the first one has its bar code scanned, empty-bottle infeed is halted automatically at the filler. This allows all bottles with label A to empty out of the line and make their way to the bottle packer. Once the bottle packer sees no more bottles with label A, it sends a signal to the bottle stop at the filler infeed to resume letting bottles in. This approach prevents bottles belonging to one batch from wandering into another batch.

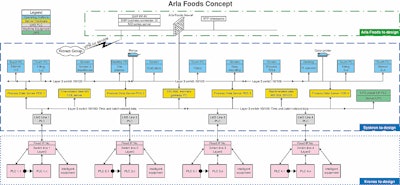

Diagram summary

Figure A summarizes all of the hardware and controls integration components required to make the four new packaging lines operate. The bottom level, in pink, represents equipment: labeling, filling, capping, induction sealing, and trolley-packing machines. All of this equipment has a fixed IP address on an Ethernet connection. Regardless of which vendor manufactured the equipment’s PLC, the machines are all networked, and it is via this network that manufacturing orders are received.

Above the equipment layer, and shown here in gray, are four PLCs that run the Line Management System software from Syskron. One layer up are four Process Data Servers that are colored yellow. These collect whatever data needs to be logged for trends analysis.

Between Process Data Servers one and two is a Microsoft SQL data base server in which all time-related data that’s been collected in Process Data Servers 1 and 2 is stored. The SQL data base server has greater capacity for long term storage than the Process Data Server.

Between Process Data Servers three and four is a Microsoft SQL data base server that stores batch-related data collected by Process Data Servers 3 and 4.

Connected to each pair of Process Data Servers is what Syskron calls a “gateway PC” that, thanks to certain modules it has, connects everything to the Arla Foods ERP. Arla’s ERP program was supplied by SAP. Among the modules on the gateway PC is an FTP (File Transfer Protocol) server that sends files back and forth from the ERP to the layers below. Another module on the gateway PC is an XML ISA-95 interface that permits real-time information to flow from ERP to plant floor and back to ERP in a closed loop. “The ISA-95 standard gives us naming conventions that let us get production orders from the ERP system down to the shop floor,” says Vonsild.

It all comes down to a matter of translation. Historically, ERP software has not been ideally suited for accessing real-time data from the plant floor. ISA-95 is essentially a translator that translates from one network protocol to another, from a top-level business protocol to a plant-floor manufacturing protocol. A business-to-manufacturing markup language (B2MML), it tells dissimilar network protocols how to construct a standard for communication. It’s a metalanguage that says, “This is how you format your data for an exchange of information that is understandable on both sides.”

Real-time view

Returning to Figure A, one layer above the four Process Data Servers and shown here in blue are the screens where, thanks to HMI software, Arla personnel get a real-time view of what’s happening throughout the blow molding/processing/packaging system.

Figure A is useful because it shows how four lines are, in essence, one line whose many discrete machine components are all tightly and directly integrated to Arla’s ERP system. Figure B, on the other hand, shows a single line, Line 4, modeled in the manner of a batch process that conforms to S88 terms and concepts.

“It’s a batch processing approach to packaging,” says Syskron’s Klaus Doppler. “Take labeling, for example. To operate labeling under S88 methodology, you can’t think of the labeler as a single unit. You need to identify functioning units or function blocks within labeling. Relying on standardized S88 terms for machine states, you then string those functioning units together. An action starts and finishes, and as soon as it finishes, that finished state is communicated to the next functioning unit so that it can perform its function.”

In Figure B, the functioning units Doppler refers to are outlined in red. When an operator at an HMI screen sees that it’s time to change from Label A to Label B, he loads a new label roll onto the infeed station of the label splicing unit and attaches the leading edge of the new roll to the splicer. He also acknowledges, at the HMI screen, that Label B is ready to be spliced. When the set point for the previous batch is reached, the labeler automatically slows to half its normal operating speed, and Label A is cut so that Label B can be spliced to the tail end of A. Now it’s label B that proceeds to the labeler. Production slows for a label change, but it never stops.

“We change labels on the fly,” says Vonsild. “The Line Management System keeps track of which bottles received labels near the splice and automatically rejects the bottle before the splice, the bottle with the splice, and the bottle after.”

The flow of information from ERP to plant floor and back again is so thorough it’s as if multiple batches are in production simultaneously, says Doppler.

“A batch order is sent from the ERP to our Line Management System, which splits that order into sub-orders for each packaging machine. The net effect is that each packaging machine, at any point in time, has all the information it needs to execute not only a current batch but the next batch, too, so that operators can be ready with the correct supermarket brand label or cap color when the next batch goes into production. Operators stay on top of which batch is next by checking the nearest HMI screen.”

Worth pointing out is that everything described above is happening in a plant where filling speeds are brisk, to say the least. The 4-pint line, for example, runs at 345 bottles/min. Yet the real-time data acquisition capabilities available through the Syskron Line Management System are so powerful that if any bottles are rejected due to leakers or skewed labels or cocked caps, the number of rejects is communicated to the upstream labeling machine so that it knows it has to label one more bottle to make up for each reject. Features like this have made Vonsild a big fan of the Line Management System.

“The sheer number of labels and frequency of changover here creates a strong risk for the wrong labels on bottles, or wrong ink-jet codes on bottles, or the wrong cap color,” says Vonsild. “But the Line Management System prevents mistakes like this. The complete spec is downloaded and all equipment is set according to those parameters.”

Vonsild also emphasizes that Arla’s chief goal behind implementing this “new way of doing things” was not merely flexibility for flexibility’s sake. It’s really about quality. It would appear that goal has been met.

“The industry average in the UK for customer complaints per million units is 50 times higher than complaints we’re getting on these new lines,” says Vonsild.

He also believes that the benefits gained from the automated order system can be extended.

“With the detailed information you get on every single bottle, there’s no limit to what you can do next,” says Vonsild.

For a complete list of suppliers mentioned in this story, see: packworld.com/go/w156