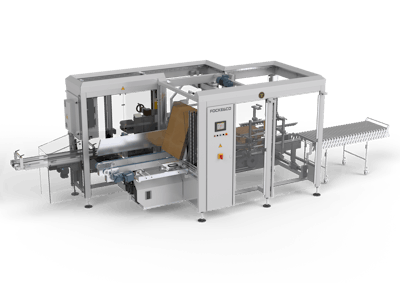

The Focke 459 product range can be used for a variety of products and case types, including food, hygiene products, or confectionery. The machines are designed for non-stop runs and can be collated on various infeed systems that support the end user’s customized case orientation.

“The compact machine concept includes case erecting, filling, and closing in one machine frame,” says Jay Jimenez, Focke regional manager. In addition, the 459’s clean design avoids dirt settling and allows easy cleaning. For example, an open design and reduced horizontal surfaces prevent accumulation of dust and product residuals. “We’ve taken the design and we’ve inverted it 45 degrees, reducing the amount of flat level surfaces, so that particles and debris can slide off,” he adds.

Focke can change the direction of how product goes in and comes out of the case packer. “We also offer a version that comes in, say from the north, and can exit to the west or to the east,” Jimenez explains. With it, 90-degree turns can be made, and the equipment can be reversed and set up in a U shape.