The Twilight Zone captured the imagination of huge TV audiences with chilling tales of science fiction. As host Rod Serling opined some 60 years ago, “It isn’t enough for a sole voice of reason to exist.”

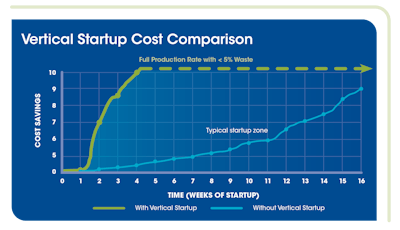

Those words could not be truer today, particularly in the case of achieving vertical startup of your company’s capital projects. Vertical startup—in which new operations reach full production quickly—will accrue benefits to all aspects of the business, so it stands to reason to enlist several voices of reason, engaging all functional areas as “investors” in the project’s success from Day 1.

Vertical startup requires a full commitment of cross-functional leaders and stakeholders to the success of the project—investment of key resources early on and a regular review and oversight process to quickly provide direction, eliminate barriers, and react to the unexpected challenges.

This new commitment to vertical startup of the project begins by creating BOA (buy-in, ownership, and advocacy) among all stakeholders. It has been proven to be a force multiplier to deliver the company’s key initiative. Some formerly “unimaginable results” include:

- 85% reduction in startup waste

- Additional 450,000 lb of finished product

- Full production reached 12 weeks faster, and sustained

- Well trained and engaged employees at all levels

Contributing to the vertical startup discussion for this article are two industry leaders and FSO Institute coaches: Paul Schaum, former COO and CTO of Pretzels Inc., and Mark Cacciatore, former senior vice president of operations of Conagra, and Campbell Soup.

FSO Institute: Paul, these results noted above were from your recent project. When you were the chief technical officer for a mid-size snack food manufacturer, can you describe how you successfully engaged others in the senior leadership team to fully support vertical startup?

Paul Schaum: Our company’s business driver was meeting the customers’ demands for capacity and quality. Beginning with the end in mind, I shared the data of past projects done the traditional way—engineering owned the project and turned it over to production when construction was complete. In that approach, expectations, timelines, and budgets were rarely met. Most importantly, full production at the required quality levels took many months to achieve and sustain. That loss of time and product was a significant limitation to our ability to meet customers’ needs.

Recognizing the limited resources available as a smaller company, we had to develop a plan that created BOA in all key departments. This was crucial as all individuals involved realized this effort was a vital—and additional—part of their job, while all normal functional responsibilities remain.

The all-hands-on-deck commitment was certainly difficult at times, particularly in the early stages. For example, purchasing questioned why they should be engaged so early before the project was completed (“we never had to do that before”). Vertical startup requires sustained operational reliability and, as a result, purchasing had to be aligned with demand forecasts for each period going forward. We could not afford to run out of materials and ingredients with the accelerated production.

The plan was also to hire the operators, supervisors, management—basically begin staffing the plant six months before the project concluded, not wait to hire until the last two weeks. This major investment is directly correlated to the ROI from reduced waste (85% less than normal), expanded capacity, and the quality of product that exceeded customer requirements. The time spent training, onboarding, getting comfortable with the equipment, maintenance helping with installation all contributed to hitting and maintaining full production. What’s more, the teams on all shifts were so engaged that the retention rate of the factory floor personnel exceeded all historical records.

For our company, the biggest result was the continued high performance of the team and manufacturing lines after one year of operations. The real value is in achieving sustained operational excellence, and we did that.

FSO Institute: Mark, your career has been with large multinationals with considerable capital expense budgets. Can you describe the value vertical startup made in your experience?

Mark Cacciatore: As leader of a large food manufacturing/canning facility, I had the opportunity to put these tenets to practice as the site was awarded significant capital to start up the first aseptic packaging line in the company. Of note, a large capital investment just two years before had a very poor startup, resulting in significant negative business impacts. Given this past performance, management viewed investing in a new line of business at the facility as risky. As such, success of the project was critically important for the future of the plant.

The site leadership committed to a different approach, incorporating vertical startup best practices to not only win approval for the project but, in the end, deliver the best new-line startup in company history. The project started up three weeks early, below budget capital and expense, and delivered 87% overall equipment effectiveness (OEE) in month one with continued improvement to 90+% in succeeding months. This operation quickly became the benchmark performer for the entire division and the learning and training ground for operational excellence across the company.

In my experience some key takeaways include:

- Gain commitment from all cross-functional leaders and stakeholders. It is crucial to the success of the project to get personal engagement of leaders, with joint ownership for project deliverables, including startup and ongoing performance metrics.

- Organize the project with a strong cross-functional project delivery team, including a dedicated delivery leader (ideally the operations leader responsible for the ongoing operations). Additionally, identify a cross-functional leadership project steering team that provides a decision-making forum to help eliminate barriers, resolve conflicts, or provide resource needs.

FSO Institute: Paul and Mark, given your career experiences of operational responsibilities and large capex projects, you have both expressed a powerful view of manufacturing readiness. Can you share a final thought?

Cacciatore: For manufacturing readiness, a commitment to staff the project at the very early stages with high-quality talent is critical. Key roles include a dedicated startup leader, maintenance leader, line leader, and safety and training resources.

Schaum: Lessons learned from vertical startup contributes to the daily requirements of manufacturing readiness—worker safety, product quality, personnel engagement, and performance efficiencies. Achieving “first hour full power” following changeovers is a direct beneficiary of vertical startup.

Vertical startup is a proven winner in capex projects and can be equally transformative to the organization. How’s that for unimaginable results?