Just who is Michael Gerber and what in the world does his classic treatise, The E-Myth, have to do with improving your manufacturing health? It’s pretty simple: When you’re so busy working in your business every day, you don’t have time to step away and assess how the business is actually doing. So, by making time to work on the business, as Gerber implores, you can see things in different ways that allow you to assess how the business is doing, make the necessary adjustments, and improve the overall manufacturing health of your operation.

There is certainly no shortage of tools and processes related to working on the business for improved manufacturing performance and health, including Kaizens, Gemba Walks, 5S, Lean, Six Sigma, and the like. Some of these are more complicated than others, and some require certification. But there are some simple, common sense assessment tools and processes that come from years of experience working in leading consumer packaged goods (CPG) manufacturing companies.

To tap into this experience, FSO Institute coaches Paul Schaum and Dan Sileo identify below some of the simplest, easy-to-implement tools and processes for you to consider as you make time to work on your business to improve performance and overall manufacturing health.

FSO Institute: Dan, throughout your career you have been a big fan of working on the business. From your experience, what is the best way to get started?

Dan Sileo: Working on the business is strategically important, but we have found that too many leaders choose not to prioritize it due to the daily crisis. There is time for firefighting, but to win consistently, a change is needed. We often recommend the best way to get started is to discover where the greatest pain points are, prioritize them, and then take a targeted approach that is focused on achieving quick and meaningful wins. As one of our colleagues is fond of saying, “Don’t try to boil the ocean” and that is so true. Working on the business is a journey and not a “program of the month.”

FSO Institute: Paul, like Dan, you’ve spent a good bit of your career with continuous improvement initiatives and other leadership initiatives in working on the business. What comes after the discovery phase?

Paul Schaum: Totally agree with Dan’s comments. At Pretzels, we chose to limit the scope by improving just one or two packaging lines to start. We considered this a pilot or proof of concept. The pilot needs a specific purpose or theme such as War on Waste. By involving line operators, supervisors, and other key stakeholders, you have in a sense created a SWAT team approach to solving the problem. This will not only deliver bottom-line results but also build confidence in all the stakeholders that, through their efforts, they too can make a meaningful contribution to the company and their work.

FSO Institute: Dan, you’ve used Managing for Daily Improvement (MDI) before when working on the business. How does MDI work?

Sileo: Paul used the War on Waste as a strong improvement approach to securing early wins for the company. Those and other continuous improvement events need an overarching transformation process to sustain the results. That is MDI. Its primary purpose is to identify and solve problems and grow people. Growing people is truly working on the business, as they now make good decisions on your behalf. It is visually intensive communication on the factory floor to enable the operators and supervisors to track their KPI performance in real time. This information is powerful in aligning towards winning the day, every day.

FSO Institute: Paul, another big step in working on the business is getting team alignment. In your War on Waste, how did you go about getting everyone on the same page?

Schaum: Alignment is key to any game plan to achieving and sustaining its successful outcomes. Can you imagine an NFL team’s record if the offense is not aligned in executing its game plan? Leadership at all levels has a responsibility to both communicate and support throughout the organization. At the floor level, supervisors are leaders and they must work with their operator teams to perform at their best (role clarity). To do that effectively, the supervisors must understand (be aligned) with what plant leadership expects. Obviously, therefore, plant leadership must in turn be fully aligned with company leadership.

FSO Institute: Paul and Dan, this question is for both of you. What are the most significant things to consider in putting together an action plan for achieving operational excellence?

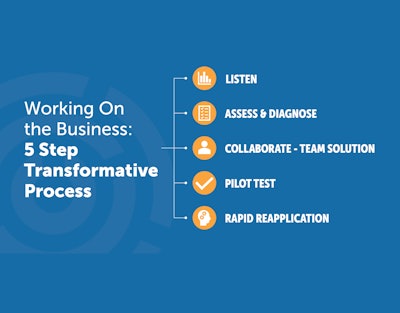

Schaum and Sileo: We both agree that, through our experiences, the most effective plan for achieving operational excellence is a walk-to-run strategy. This may come in the form of a 100-day plan that involves all levels on this path to operational excellence:

Listen—Assessing how the company’s vision and mission is communicated (and understood) throughout the operations group.

Diagnose—Using data, surveys, and focus groups to establish a clear picture of the current state, forming a basis for solving the right problems.

Collaborate—Engaging with the key stakeholders for developing solutions and determining what would be required, such as standard work for operators and leaders, just-in-time training for upskilling, and problem solving.

Pilot—Running a proof of concept to validate the plans, engage all stakeholders on the improvement, and determine the effectiveness of KPIs.

Rapid Reapplication—Following a rigorous Plan-Do-Check-Act (PDCA) to develop the rollout to other lines and plants.

Finally, throughout the journey, conduct feedback sessions with senior management to assure alignment, clarity of purpose, and course corrections if needed.