Across industries, many designers and engineers are looking to learn lessons from nature to solve human-made problems in more sustainable ways. Whether applied toward improvements to form, process, or ecosystem, the term biomimicry becomes more popular with each passing year, but it’s not always used with care.

The biomimicry methodology is a carefully crafted framework from Biomimicry 3.8, a consultancy that helps innovators find design solutions from nature’s wisdom.

We talked with Dr. Dayna Baumeister, co-founder of Biomimicry 3.8, who has worked in the field of biomimicry with business partner Janine Benyus since 1998 as a biomimicry thought leader, business consultant, and professor. Biomimicry 3.8 has helped more than 100 companies consult the natural world for elegant and sustainable design solutions, including Microsoft, Nike, Interface, General Mills, Seventh Generation, and Procter & Gamble.

Given that there’s an entire master’s course dedicated to the subject, there’s more to it than can be covered in single article. But, here are a couple of details that are helpful to know before we dig in:

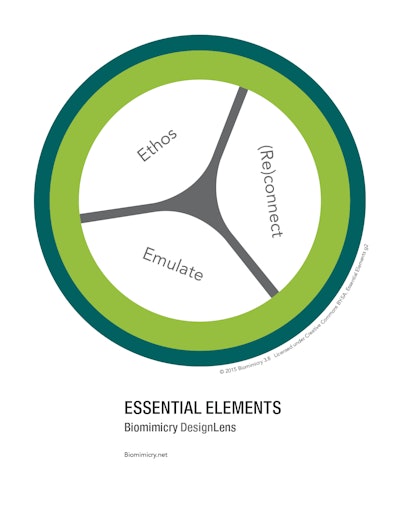

- The biomimicry practice features three essential, interconnected elements: emulate, ethos, and re-connect. Read more about these three elements here.

The three essential elements of biomimicry.Biomimicry 3.8. Licensed under Creative Commons BY-SA.

The three essential elements of biomimicry.Biomimicry 3.8. Licensed under Creative Commons BY-SA.

- Biomimicry is guided by Life’s Principles, a set of 27 design lessons from nature. These are patterns found in species surviving and thriving under the same operating conditions on Earth that we humans are subject to. Biomimicry 3.8 recently released its latest version of Life’s Principles in September 2023, which was the first update in 8 years.

Here, Dr. Baumeister shares some important tips for tapping into innovation, shifting from closed loops to connected flows, and more.

1. Jumping straight to emulating nature

Emulating nature’s genius for human problems is an attractive prospect. A common example is the Shinkansen high speed bullet train in Japan that used inspiration from the kingfisher’s pointed beak to travel more quietly, without sacrificing speed or efficiency.

But choosing a species as a mentor and jumping straight into emulation without thought for the ethos and reconnect elements may not offer the broadest solution. “Even using ‘emulate’ alone—whether or not you want to make it sustainable—is sexy. Innovation is sexy. You learn something and you get an idea and you run with it,” says Baumeister. “The reason why we have the other two essential elements of ethos and reconnect is for multiple reasons. One is that it allows you to actually really tap into some far more profound types of innovation if you make the choice to see the organism as a living being, to see the organism as part of its context.”

Baumeister adds that part of reconnect is recognizing that we are nature and that as humans, we are part of our larger ecosystem. “Reconnect gives us the opportunity to take a full-on systems perspective to how we learn from this mentor. Therefore you get a much richer experience in the lessons. In fact, you'll probably find that the organism you first found may not be the best teacher for your challenge. So that opens it up and it makes for a better emulation.”

Considering the other two elements also helps you see the larger picture and implications of the design. “When we're connected with nature and we see all of the interconnected and the interdependent elements, then we're just better designers,” she explains. “Then the ethos piece is to avoid just cherry-picking some cool ideas and not recognizing that there are larger implications of these designs. We need to think about not just what we design, but how it fits in the system, what happens to it in the full length of its time. The ethos demands that we ask those questions, not just what are we learning, but where are we applying this and how are we giving gratitude to our teachers? Do we have a full circle recognition of where that brilliant idea came from in the first place?”

2. That pesky status quo

As professionals in packaging and manufacturing innovate, there are gradients for using nature as inspiration. Baumeister says she’s seen folks find the first cool thing and run with it, emulating nature in a shallow way and losing the opportunity to tap into some real brilliance. “The other thing is there may be a misconception as with a lot of design, that it's just a matter of replacing option A with option B and all will be good,” she notes.

She recalls a project where she worked on food packaging. The client was explaining the closure on the packaging—they sought something that opens and closes like a Ziploc bag. Her mind was already turning with interesting possibilities where nature might inform that. Then they said they wanted it to run on the same equipment, using the same material, produced at the same speed, and cost less than a penny a package.

She recounts: “I said to them, ‘I'm sorry… with those kinds of criteria I can't help you.’ They said, ‘That's okay. We want you to go [ahead] anyway because we've interviewed 40 other people before you and none of them had a solution and you're the last on the list.’ I thought, ‘I don't know if that's a compliment or not, but we'll go ahead.’”

In the end, the project found success—the company obtained three patents out of the work they did, but they also had to relax their criteria. “They had to recognize that those were ridiculous criteria for innovation. You have to be able to open your boundaries. They came up with some pretty fun pieces that were inspired by the Venus flytrap. It was a great project,” says Baumeister. “So maybe a misconception is that you get to keep doing the status quo. If you really want to do innovation, you’ve got to be willing to expand the possibilities of what might come out of it at the end of the day.”

This can be a tougher sell for those in life sciences and foods, both regulated markets with an established suite of compatible materials, but not impossible.

3. Innovation takes serious investment

Truly innovative materials do not come cheap. “We've worked on a couple of packaging projects, and especially when you get into the material chemistry, that's where the real innovations can happen. That takes time and real development dollars,” Baumeister says.

Clients have come to her asking, “Can't you just come up with a substitute for plastic bags?” The answer is technically yes, but not for a hundred-thousand-dollar budget. This sort of innovation requires an in-depth R&D process and investment.

Chemical companies, she says, have put so much infrastructure into the current way of producing materials that they're less inclined to innovate: “Even the PLA plastic that’s biodegradable, I think it was something like $50 or 80 million of R&D went into producing that… it still requires an industrial composter and uses bio-engineered organisms to help produce it.”

Baumeister says that if we really want to solve the problem, we have to fundamentally rethink things. (From the archives: Many years ago, they covered nature's packaging in the Whole Earth Catalog here, where they played with some of the possible ways to think about packaging in different ways.)

4. Bioutilization is not the same as biomimicry

Terms that sound alike to the uninitiated have different meanings with different implications.

Where “biomimicry” is the conscious emulation of nature’s genius, “biomorphic” designs visually resemble natural elements. They may be beautiful, but there isn’t necessarily a sustainability win. Per the Biomimicry Institute, “bioutilization” is the use of biological material or living organisms in a design or technology, such as the use of wood in homes, mushrooms for molded packaging, or microbes in drug development.

“There's an umbrella term now of ‘bio-based,’ which could be anything and everything. We have to be really mindful because I agree that the ethical implications of casually lumping all of these into one bucket really misses some fundamentally different mindsets and philosophies behind them,” Baumeister says. Dr. Dayna Baumeister, co-founder and partner, Biomimicry 3.8.

Dr. Dayna Baumeister, co-founder and partner, Biomimicry 3.8.

5. Closed loops vs. connected flows

Earlier, we mentioned Life’s Principles, 27 design lessons from nature. In the recent update, Biomimicry 3.8 altered one pattern from “keeping all materials in a closed loop” to “keep all materials in connected flow.” (For a 15-minute video on the new version of Life's Principles, see video here).

Baumeister explains the rationale behind the change: “It's partially to help people think a little bit differently. It's kind of a misnomer—the circular economy is often captured in a loop, and it's the same even with our triangle with the arrows. If we only think about ‘How can I turn a glass bottle back into a glass bottle?’ That's not the way nature works, leaves don't turn back into leaves… when a leaf falls in the autumn, maybe 5% of those molecules might end up back as leaves the next year, but it's really a system of flows.”

She says there are two parts to that. First, recognizing that material use is not necessarily circular, at least in the sense of an object going right back into the same object. “It also means that whatever you produce needs to be of value for a larger portion of the ecosystem,” she says. “For natural systems that are non-human, everybody's using carbon and oxygen and hydrogen and nitrogen… those are great building blocks. So there's value for anybody in that web of flow.”

Second, she highlights, “Flow is a noun and a verb. It also honors that the value comes when things don't get stagnated—the value comes for the system when they stay in movement, they stay in flow. Timescales vary, of course. This is a very different way of thinking about landfills. Landfills are in one end, out the other, and then it's done. All of that materiality, all of that value is just stagnated into a pit in the ground. How crude of us, especially with these fancy and high-end and elegant materials, and we just stop its full potentiality. It's mind-boggling.

“So that was why that word change was designed, to help us recognize it's more true to what's happening in biological systems, and it needs to be more true for how we go about designing a circular economy."

Baumeister’s sentiment here echoes voices in the packaging community, and specifically the HPRC's vision. At the[PACK]out conference in 2023, Nick Packet noted of setting up recycling programs, “… where is the resource being generated? I hope you notice I didn’t use the term ‘waste.’ I think we need to get away from that because waste means it doesn’t have any value. So how do we change that mindset and think of packaging as a resource?”

6. Restricted by regulations—getting creative

For those who are restricted by regulatory requirements such as those in FDA-regulated healthcare packaging spaces, it can be difficult to change materials once validated. But Baumeister advises that there are still ways to apply biomimicry thinking:

- Form: You can emulate nature in form. “So you can still use the same materials, but perhaps because of the way you've put the form together, you actually could save [resources],” she says. “For example, there's a water bottle that Logoplaste designed. By mimicking the spiral that happens in bristlecone pine trees and adding that—and not a perfect spiral, but an imperfect spiral—they were able to reduce something like 18% of the amount of plastic in the bottle because it still had the same rigidity. So there, suddenly you have massive cost savings and of course less plastic used.”

- Process: You can also experiment with process—your manufacturing process, your distribution process, your labeling, and even product status indicators. “There's a pretty cool product out there that is kind of like a Saran wrap. The inspiration may have been the Venus Flytrap also, which has a concave/convex trigger mechanism,” she says. “The way this packaging worked is when exposed to ethylene—which is what food produces as it begins to rot—the packaging would invert from concave to convex. That inversion created a color change. So you could put it on food packaging and instantly see that your food is starting to go bad, not because of a date stamp, but literally because of the ethylene production inside. So if you think about some of the processes in which your product engages with the packaging, by learning from nature, there's a lot that can happen there.”

- System: Baumeister says you can mimic system-level concepts and ask questions like, “We still have to use this same material, but what happens to it at the end of its life? Or at this stage of its life, where else can it go? What else can it do?”

She notes that especially in medical packaging, particularly with questions around risk and biological contamination, there's an inordinate amount of packaging waste: “If that's the case, then what does it look like for us to make low-cost packaging that still could have value where that waste is not of a biological risk? And what does that look like?”

Could the packaging be turned into biochar? (Though she notes that the pyrolysis process requires extremely high temperatures.) “Biochar often goes into soil. As soil amendment it helps retain nutrients, retain water, helps increase nitrogen in the soil, and so on. But if that's a place we're growing our crops, we might worry about biocontaminants,” she explains. “But because biochar fixes carbon, one of my colleagues is working on what if biochar replaced the granular pieces in roofing shingles? So now you've got this hardened material that serves the purpose of your roof, but it's also fixing carbon and getting harder over time versus weaker over time. Where are they going to get the biochar from? You don't want to compete with the farms, but what if it was, say, waste from the medical industry that was able to create the biochar? So, thinking in that system way can result in some pretty important breakthroughs in the problems that we're trying to address.”

It's a promising message, considering all the current hurdles preventing a used life science package from becoming a new life science package. Using recycled materials in healthcare requires traceability and sorting, not to mention the technology, energy, and infrastructure to efficiently recycle high performance, multi-layered packages.

A connected flow is a more practical target than a closed loop, if nature is to be be-leafed (I'll see myself out). Don’t forget to get outside!

Next steps: Want to learn more about biomimicry? Check out the following for more:

- AskNature.org, a collection of brief biological strategies and innovations is managed by the Biomimicry Institute

- Biomimicry.asu.edu, the program at Arizona State University

Related reading:

Sharks: From Mortal Foes to Medical Inspiration

Bio-Inspired Retrofit May Save Manufacturers Millions of Gallons of Water

Biomimicry Institute Highlights Startups in Circularity, Waste Reduction

6 Tips for Preventing Use Errors in Packaging Design:

Dr. Bryce Rutter says that you may look at a bug and see a certain texture that works for non-slip conditions. “I think nature is a tremendous source of inspiration and really allows you to step back from being totally immersed in the very narrow field or category that you're working on,” he notes. “Walk around with your eyes open. The world is your laboratory and a lot of the tests have been done, you just need to figure out what you're looking at.”