This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

The ASRS will automatically store drill bits, machining parts, and raw and work-in-progress goods while also acting as the facility’s tool crib to consolidate several areas of storage around the facility.

The facility had previously used a carousel to manage much of the raw good storage, however the system was becoming costly to maintain and frequently broke down, reducing workflow efficiency and operational stability.

The new Hai Robotics’ ASRS, driven by autonomous case-handling robotic (ACR), delivers to a single dual-purpose workstation and conveying systems. All unified with Hy-Tek’s IntraOne software.

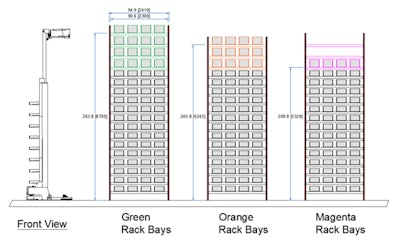

The facility has variable celling heights and other obstacles like pipes, lights, and sprinklers, that created inconsistent vertical clearance. The Hai Robotics/Hy-Tek solution has 3 racking heights, 22 ft, 20.5 ft, and 17.5 ft. Other ASRS typically require a uniform height, requiring the max height of storage to meet the lowest clearance opportunity – losing out on vertical storage. This extreme flexibility of the ACR driven ASRS allows the system to maximize every inch of vertical storage space permitting 3,904 storage locations.

The ACR driven ASRS is flexible and intelligent enough to handle 2 different size totes within a single system. The length and width of each tote is the same but have variable heights based off the products that are to be stored within them. This flexibility creates an appropriately sized system that consolidates much of the facility’s storage needs. If the system only had the large totes, the system would be undersized and storage locations lost, or only the smaller totes would exclude some of the products. The ability for an ASRS to manage such a wide variety of material sizes proves the facility with substantial operational advantages with the added benefit of more open space through the facility.

The A42TD ACRs, the robot model that manages this ASRS, has a double deep reach, meaning, the robot can reach 2 totes deep into racking. Totes can be stored 4 deep and retrieved on either side of the rack. As a result, aisle numbers are reduced and the storage footprint is condensed.