The two new models with their magnetic 24V encoder were developed by Nanotec for integration into IP-protected motors. The encoder generates 1024 increments per revolution. With the 24V connection at the encoder, the motors are particularly well-suited for direct control via a PLC or a higher-level control system, but can be controlled using Nanotec control systems as well.

The option with a safety brake (1 Nm of holding torque) is typically used wherever vertical loads have to be kept in place even during a power failure or an emergency stop in order to prevent damage to persons or property. This applies to Z-axes and other safety-critical applications.

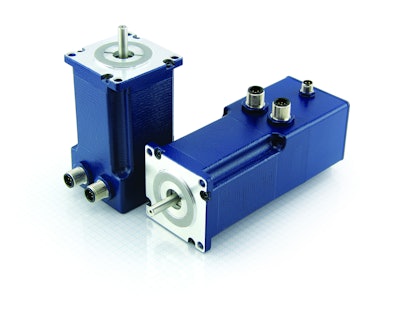

Featuring a holding torque of 1.98 Nm, the AS5918-EMN24 and AS5918-EMN24B stepper motors are viable alternatives to servomotors with gearboxes in Torque Mode and Closed Loop at low speeds. This is because they are more compact and have greater energy efficiency, whether in mechanical engineering devices or other systems where operating in a harsh environment and precise positioning are crucial.

The motors have a high degree of electromagnetic compatibility and feature M12 and M8 connections. With a flange dimension of 56 mm (NEMA 23), they are compatible with all Nanotec stepper motors and can be used in mixed environments.