This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

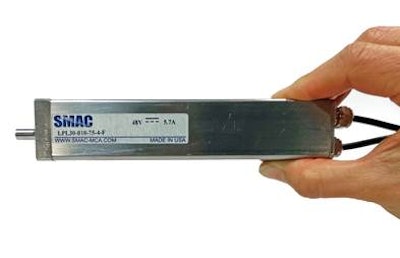

Using a DC linear servo motor, the SMAC LPL30 low-profile electric linear moving coil actuator offers programmable speed, force up to 70 newton, micron-level positioning, and a 30 mm-pitch that is ideal for dosing and dispensing applications.

Other features of the LPL30 include:

- Response time variation of +/-1 millisecond and a dose volume variation of 1%

- Programmable stroke that can be adjusted in real time to compensate for valve wear or change in diaphragm size

- Fast, consistent response times and force that remains steady throughout the stroke

- Cycle rates up to 2,400 cycles per min for increased output

- Industry 4.0 compatibility

- Patented “Soft-Land” capability to gently locate a surface and then perform its function and provide real-time feedback for tracking, performance, and quality control

- A compact size to fit most dosing and dispensing machines

- Ingress Protection (IP) 67 and 69 ratings

“Machine manufacturers are quickly discovering the benefits of programmable electric actuators and switching from the air valves and air cylinders that have been the mainstay since the 1950s,” says SMAC Founder and CEO Ed Neff. “The precision the LPL30 provides means the exact quantity of is dispensed every time, even at very high speeds.”