This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

beRobox introduces STACKiT 2.0, a major software upgrade that eliminates configuration guesswork with stack validation while transforming daily operational efficiency

As provider of easy-to-use palletizing solutions, we are proud to announce the release of STACKiT 2.0, a significant upgrade to its proprietary palletizing software. This release introduces features that fundamentally change how operators interact with robotic palletizers, reinforcing beRobox's commitment to true plug-and-play automation.

Stack Validation: Solving Problems Before They Occur

STACKiT 2.0 introduces Stack Validation that analyzes palletizing patterns during product configuration, instantly detecting potential collisions and robot reach issues.

"We realized operators don't need the traditional slow and complex simulations – they need to quickly know if the stack pattern will work without issues.” said Charles Maheu, Head of software development at beRobox.

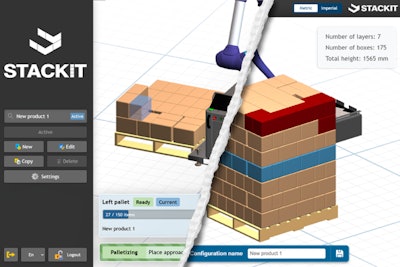

Redesigned Operational Interface with Dynamic 3D Visuals

The completely redesigned interface provides operators with the information they need at a glance, further reducing training time and operational errors.

The new home screen includes:

- 3D view showing pallet status and upcoming box placements

- Integrated recovery mode for quick edits

- Clear visual indicators for progress and safety status

Intelligent Vertical Axis Motion

Using the specialized Stack Validation technology, STACKiT 2.0 automatically calculates optimal vertical axis movements. This improved integration allows for palletizing taller pallets while maintaining beRobox's market-leading palletizing rates.

Availability

STACKiT 2.0 comes standard with new PALTZ palletizing systems. Existing customers can upgrade through beRobox's implementation service package, which includes expert support to ensure a smooth transition with zero operational disruption.

beRobox at PACK EXPO Southeast

Visit beRobox in Booth 2522 at PACK EXPO Southeast!