This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Wintriss Controls Group has announced it will be demonstrating advanced features in its ShopFloorConnect OEE and Data Collection Software at PACK EXPO International 2024 in Booth LU-8431.

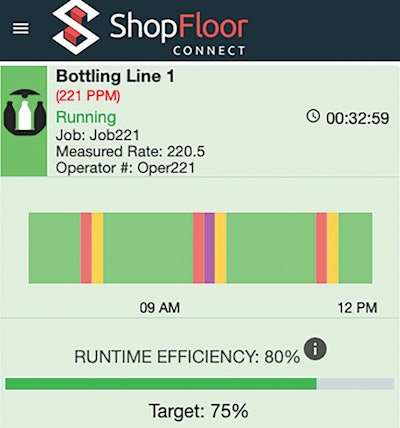

The latest functionality in ShopFloorConnect gives packaging and processing professionals efficient and easy-to-use software for increased productivity and reduced machine downtime, including when remote monitoring is required. The software can significantly increase manufacturing capacity and profitability by identifying and quantifying excessive production losses and bottlenecks.

Advanced ShopFloorConnect OEE and Data Collection Software collects downtime and production efficiency data from every machine in a variety of industries including packaging, food, beverage, discrete manufacturing, metal forming and metal fabrication. Data are displayed real-time, and indispensable manufacturing reports are produced, including detailed OEE reports in a variety of formats. At PACK EXPO, Wintriss will highlight the ShopFloorConnect Maintenance Tracker which enables users to track important machine preventative maintenance (PM) items by run-hours, calendar days or machine cycles, issue targeted alerts when an item requires PM, and track the maintenance work history for all machines.