Key trends for lifecycles in pack recycling to 2023

This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

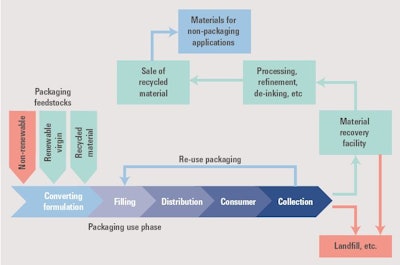

New research from Smithers Pira in The Future Lifecycles of Packaging Recycling to 2023 reveals that:

- There is a major opportunity if partners across the supply chain collaborate on recycling projects;

- Brands and retailers are setting themselves tough targets for incorporating recycled plastics content into packaging;

- Worldwide the recycling rate for plastic packaging is just 14 percent;

- Worldwide the recycling rate for paperboard packaging is 70 percent;

- Worldwide the recycling rate for glass packaging is 50–80 percent;

- Worldwide the recycling rate for metal packaging is 30–90 percent;

- Recycling saves money – for example, recycled aluminum uses 95 percent less energy than when extracted from an ore; and

- Key technologies for increasing the recyclability of plastics for 2018-2023 include:

- Repulpable coatings for paperboard;

- Substituting oxide coatings in flexible plastics to replace problematic PA and EVOH materials;

- Implementation of design for recycling programmes; and

- New sealing approaches for PET trays.

The future evolution of packaging recycling with SWOT analyses for all key industry players are included in the Smithers Pira report The Future Lifecycles of Packaging Recycling to 2023 which is available for purchase now. Save 10% off this new report with promo code PMMIREPORTS

Check out the Sustainability in Packaging US conference, March 4-6, 2019 in Chicago.