This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

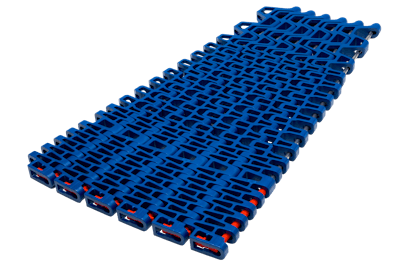

Regal Rexnord Corporation, a distributor in engineering and manufacturing solutions that power, transmit, and control motion, has announced the introduction of the Rexnord 6400 Series KleanTop Plastic Active Drive Spiral Cage Belt. This modular belt is part of Regal Rexnord’s comprehensive line of plastic and metal spiral belts and powertrain offerings, providing food manufacturers with solutions designed for greater productivity, enhanced product handling and reduced maintenance in demanding spiral cage applications.

In today's food processing environment, operational and maintenance teams are seeking ways to increase throughput, minimize downtime and ensure peak performance. The 6400 Active Drive (AD) Belt addresses these needs and is designed using a standard 1.5-inch pitch modular belt, which provides a robust, actively driven system that allows facilities to run wider, faster and longer with confidence.

"Our customers in the bakery, snack, protein and fruit and vegetable segments are looking for innovative ways to boost their production capacity while simplifying maintenance," says Jeff Garwood, Senior Global Product Manager. "The Rexnord 6400 Active Drive is engineered to deliver ease of installation and repairs while boosting throughput. The belt’s “Active Drive” engagement, combined with features like PowerKey™ technology, translates directly into increased productivity, less product waste and fewer operational headaches."

Key Advantages for Maximized Performance and Simplified Operations:

- Up to 25% more belt carrying capacity via PowerKey technology: Increase efficiency and productivity with a design that allows for greater product volume, helping meet high-demand production targets.

- Enhanced product handling and registration: Notched bar caps drive the belt, reducing pulsation and surge as seen in low tension driven systems.

- Reduced system construction costs: The lateral stiffness of the belt design and the use of stainless steel rods mean fewer support rails are needed in your spiral cage system, creating lower drag and tension and ultimately a more cost-effective setup.

- Material offering: The belt is available in our blue self-extinguishing (BSE) material, which provides a low-moisture-absorption, self-extinguishing product that has the strength and rigidity of acetal material.

- Extended belt life and easier maintenance: Patented PowerKey technology ensures better tension distribution and simplifies splice repairs, assembly and disassembly, leading to less downtime and an extended service life. The actively driven system self-manages tension, eliminating the need for constant overdrive adjustments.

- Improved hygiene and safety: With over 45% open area, the belt enables thorough cleaning and sanitation.

The Rexnord 6400 Active Drive is ideal for proofing, cooling, freezing, and buffering applications. It is backed by Regal Rexnord’s leading industry engineering as well as comprehensive field service installation, cleaning and maintenance training, and technical support.