This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

The Hard Cheese Grating System is purpose-built to deliver consistent, high-throughput performance for industrial cheese grating applications. Designed to handle the hard cheeses—like parmesan, romano, and asiago—this system ensures optimal texture, minimal waste, and maximum efficiency.

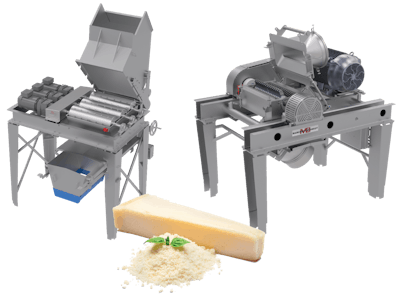

The Marchant Schmidt Pre-breaker is intended for the primary stage, course reduction of hard cheese prior to finished grating in the High Speed Mill. Blocks or wheels of cheese are conveyed into the pre-breaker where drum rollers reduce the product into chips and fragments. The coarsely reduced cheese is collected in a metering conveyor and carefully metered into the mill.

The Marchant Schmidt High Speed Mill is ideally suited for grated product, it may also be applied to soft crumble applications. The mills are intended for cheese converting plants with high-volume production requirements. The large model SC2032 produces a constant stream of grated product up to 8,000 lbs/hr. while the smaller model SC1624 produces up to 3,000 lbs/hr. The mill spins a shaft at high speed, while blades or hammers, that are affixed to the shaft, pulverize the cheese until small enough to pass through the desired sized opening in the screen. Product is dispensed onto a conveyor for further processing.

Key Features of Hard Cheese Grating System:

- Heavy-Duty Grating Technology

Engineered with robust stainless-steel components, the system powers through dense cheese blocks with ease. - Precision-Cut Output

Customizable blade configurations allow for a range of grate sizes – from fine dust to coarser cuts. - Hygienic Design

Sanitary construction with tool-free disassembly makes cleaning fast and compliant with the highest food safety standards. - Operator-Friendly Interface

Intuitive controls, adjustable feed rates, and built-in safety features ensure ease of use and operational confidence. - Integrated Automation Options

Available with conveyor integration, inline inspection, and packaging compatibility to support fully automated processing lines.

Whether you’re producing grated cheese for retail packaging or foodservice applications, this system is your reliable solution for clean, high-quality results every time.