This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

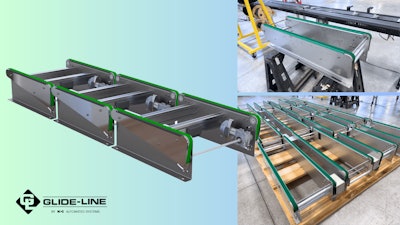

Glide-Line, a manufacturer of custom conveyor solutions, has unveiled its latest innovation: the Zero Contact Zoned Conveyor, a custom-engineered system designed to handle heavy and oversized products like automobile tires, aluminum hubs, and appliances with zero-pressure accumulation.

What is a Zero Contact Zoned Conveyor?

A Zero Contact Zoned Conveyor is a conveyor system that uses independently controlled zones to move products without ever letting them touch. Unlike traditional accumulation systems, this approach ensures gentle product handling, eliminates jams and collisions, and allows for efficient accumulation wherever it’s needed in the line. It’s especially valuable for heavy or delicate products, where contact can lead to damage, excess wear, or costly downtime.

The Customer Challenge

This project began when a customer approached Glide-Line with a unique challenge: moving heavy rubber tires and aluminum hubs directly on the conveyor belt. While Glide-Line’s standard timing belt conveyors excel in a wide variety of applications, this particular case required an alternative approach. The extreme weight and surface demands called for a thicker, higher-friction belt profile, and Glide-Line’s engineering team designed a new solution specifically to meet those requirements.

Custom Belt & Drive Redesign

To meet the customer’s requirements, Glide-Line selected a thicker belt featuring a spongier, high-friction rubber surface. This belt profile provided the necessary grip and durability to move heavy loads while protecting the products from wear or damage.

Because the thicker belt exceeded the parameters of the standard Glide-Line timing belt conveyor, the drive components were re-engineered. The result was a simple, open steel frame design capable of supporting the new belt profile, while allowing mounting of servo, AC, or DC motors depending on customer preference.

Key Features

· High-friction, soft durometer conveyor belt with a low durometer rubber coating for grip and cushioning.

· Individual zone control for every conveyed item, ensuring products never touch while still allowing accumulation.

· Zero-pressure zoned accumulation using an end-driven conveyor instead of the standard center-drive configuration.

· Durable design to handle heavy loads while minimizing wear and tear or product damage.

· Flexible motorization options, including AC, DC, stepper, or servo.

· Customizable geometry, such as conveyor size, lift stroke, and more.

Benefits of Glide-Line’s Approach

This innovation provides significant advantages compared to roller chain or traditional belt conveyors:

· Product Protection – Cushioned transport for heavy, delicate, or finished products.

· True Zero-Pressure Accumulation – Eliminates product-to-product contact while enabling smooth accumulation.

· Lower Maintenance – No lubrication, reduced noise, and fewer wear components compared to roller chain conveyors.

· Flexible & Scalable – Easily adapted to different layouts, products, and motor drive technologies.

· Time & Cost Savings – Simplifies installation, reduces long-term ownership costs, and allows integrators to focus on higher-value engineering work.

A Custom Solution for Unique Applications

The Zero Contact Zoned Conveyor demonstrates Glide-Line’s ability to engineer bespoke conveyor systems to meet the most challenging requirements. By rethinking the belt design and drive system, Glide-Line provided a solution that balances durability, flexibility, and product protection — without forcing customers to compromise.

“At Glide-Line, we bring bespoke conveyor solutions to life, offering comprehensive engineering, service, and assembly options tailored to each customer’s needs,” said Erik B., Applications Engineer at Glide-Line. “This project is a great example of how we partner with customers to solve real-world challenges and deliver conveyor technology that’s both innovative and practical.”