Bing Graffunder is president and chief operating officer of Morningstar Foods in Dallas, and his talk is as big as you’d expect a Texan’s to be.

“We think we’ll be first in the U.S. with an aseptic dairy product in a plastic bottle,” says Graffunder. “We decided nearly three years ago that as the largest dairy processor in the country, forwarding this technology was something that we should take on as a challenge. We also think a whole cornucopia of new products could emerge once this packaging technology is moved forward in the U.S.”

Morningstar, a wholly owned subsidiary of Suiza Foods, expects to launch an aseptically filled, shelf-stable, low-acid dairy product in a plastic bottle later this year.

In the meantime, the firm is gaining solid momentum and invaluable experience with an ESL packaging line that includes new equipment that began running late last year. The line is from Holland’s Stork, represented in the United States by Stork Food and Dairy Systems (Gainesville, GA).

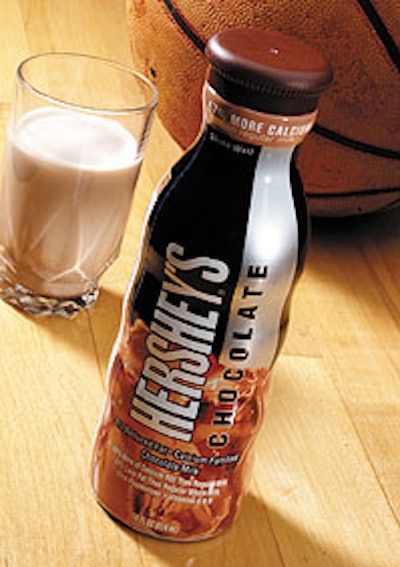

Morningstar currently uses its Stork equipment in ESL mode to bottle 14-oz Hershey’s-brand milks and shakes that have a refrigerated shelf life of about 90 days. This line, in Mt. Crawford, VA, is made up of essentially the same equipment with which Morningstar will launch its shelf-stable dairy products once it has filed for and received permission from the U.S. Food and Drug Administration to do so. Packaging World was invited recently to tour the Mt. Crawford facility.

Quickly evident upon walking into the plant is that Stork provided more than just filling equipment. It also made the ultra-high temperature tubular heat exchanger that processes the liquid product and the blow molding systems that make the three-layer containers.

So what is it about aseptic filling of dairy products in plastic bottles that makes Morningstar’s progress so notable? Low acidity. High-acid product aseptically filled in plastic bottles, fruit juices in particular, have almost become commonplace in the U.S. marketplace. But low-acid dairy products are inherently more difficult to pack in a shelf-stable format because potentially deadly bacteria that won’t grow in high-acid products will grow in an unrefrigerated low-acid environment if either processing or packaging fails to provide true aseptic conditions. So far no U.S. dairy processor has received from the FDA a letter of non-objection permitting the sale of a shelf-stable low-acid product packaged aseptically in a plastic bottle. That’s what makes Morningstar’s progress so noteworthy.

Blow molding

It all begins with coextrusion blow molding of bottles on two 15-station blow molders from Stork. Bottles currently used for ESL product are of a three-layer construction. Inner and outer layers are virgin high-density polyethylene, while the inner layer incorporates reground material trimmed from the neck and bottom flash of the bottles. To this reground material is added carbon black to block out UV rays that might threaten the flavor or nutritional content of Morningstar’s product.

Blown bottles emerge from the Stork blow molders as fully closed vessels with tops molded on. Bottles are conveyed via pneumatic tubes directly to one of three huge silos, each capable of holding up to 30ꯠ bottles. From here the bottles are drawn out and conveyed to an uncsrambler from Posimat (Miami, FL). It uprights bottles and sends them to a system that cuts off the tops and tests for leaks. Only then do bottles enter the filling room.

The Stork filler is an in-line, intermittent-motion, 12-across system with a maximum speed of 300 bottles/min. Because it accepts bottles in a horizontal orientation, a necessary prerequisite to filling is a Posimat machine that uses paddles and chutes to transform two incoming lanes of upright bottles into 12 lanes of bottles lying on their sides. A few feet later the bottles are uprighted again as they enter the fixed transport bed that takes them through sterilizing, rinsing, filling, and lidding.

The first stop inside the Stork filler is a bottle detection station. It ensures that if a lane is missing a bottle, that lane’s downstream filling nozzles will not discharge product. From here until the filled bottles have their foil membranes heat-sealed to their neck finishes, a flow of overpressured sterilized air keeps contamination out.

Next are three sequential stations that flood both the inside and outside of each bottle with hydrogen peroxide vapor. Then a series of nozzles injects super-heated air to drive out this sterilant.

Two-stage filling

Now bottles are ready for filling, which is accomplished in two stages by flow-meter valves. Once the liquid is in, the only task remaining inside the overpressured clean room zone is the heat-sealing of a foil membrane to the neck finish of each bottle. This process begins overhead, and outside of the Stork system, where equipment from Fords Packaging Systems (Kentston, Bedford, England) punches circular foil membranes from roll-fed aluminum foil. These are directed through a chute that splits the three into six and then the six into 12. The 12 chutes then lead down to the bottles through a UV light zone, which helps eliminate contamination. Foil membranes are placed onto bottles as they pass. A short distance later, 12 heat-seal tools affix 12 foil membranes to 12 bottles.

Closed bottles emerge 12-across from the filling system and are lifted by a robotic transfer unit that places them on a discharge conveyor for labeling, overcapping, and multipacking. Along the way is a Dynac pressureless accumulation system from Hartness Intl. (Greenville, SC). An expanding, spiraling loop system, it provides up to 15 minutes of valuable first-in/first-out accumulation time.

“Minimal floor space is required by this method of accumulation, and the amount of back pressure exerted on the bottles is also kept to a minimum,” says plant manager Merv Winkle.

A short distance downstream from the Dynac accumulation system are four paired machines: two shrink-sleeve labelers from American Fuji Seal (Bardstown, KY), each with a Videojet ink-jet coder from Marconi Data Systems (Wood Dale, IL) for imprinting a use-by date on the labels; two Zalkin nine-head rotary overcappers from Fowler Products (Athens, GA); two Delkor (Minneapolis, MN) Spot-Pak® multipackers; and two thermal-transfer print-and-apply labeling systems—made up of Diagraph (St. Louis, MO) applicators and Sato (Sunnyvale, CA) print engines—that put date and bar codes on each shrink-wrapped multipack. With each of these pairs, only one machine is required to operate at any one time. Should one machine go down, however, the other is ready to go. Morningstar’s Brown says this downstream redundancy is beneficial.

“If you don’t have downstream equipment that will keep up with or exceed filler speeds, you jeopardize line reliability,” says Brown. “You do not want to stop the filler because the cap hopper is empty or the labeler needs a fresh roll.”

Brown admits that one reason there are two labelers, two overcappers, two multipackers, and two print-and-apply label systems is because a second Stork filler is already on order. But, he hastens to add, when that filler is installed, one extra labeler, overcapper, multipacker, and print-and-apply labeling system will be installed as well so that there will still be redundant machines downstream from the filler ready to fill in if needed.

And how different will the filling system need to be if Morningstar succeeds in obtaining its all-important FDA letter of nonobjection for shelf-stable dairy products in plastic bottles? Not very different at all, says Brown. Foil lidding, he notes, will have to be treated with hydrogen peroxide sterilant instead of UV light before being applied. And some oxygen barrier, likely ethylene vinyl alcohol, will have to be added to the coextruded bottles. He sees neither of these as particularly problematic, and, like every other Morningstar representative that PW met during the December tour of the Mt. Crawford facility, he fully expects to begin aseptic filling on the Hershey’s line by third quarter of 2002.

“This is just the beginning,” notes Toby Purdy, senior vice president of marketing and business development. “We have a variety of new products in the development pipeline. We’re out to redefine the dairy industry.”