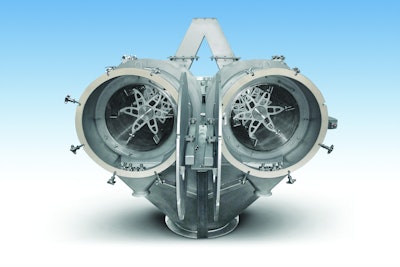

The Kason TWIN XOB-PS-SS PNEUMATI-SIFTER centrifugal sifter de-agglomerates and screens bulk materials inline with dilute-phase pneumatic conveying systems. Rated up to 14.5 psig positive pressure and 14-in. vacuum, it incorporates a feed splitter that evenly divides the flow of incoming material into two horizontally oriented cylindrical screening chambers operating in parallel. A shaft within each screening chamber rotates a helical paddle assembly that accelerates the radial movement of particles and soft agglomerates against and through the screen. On-size particles pass through apertures in the screens and discharge through a cone-shaped chute, while oversize particles are ejected via a manual or automatic valve into a sealed receptacle.