This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

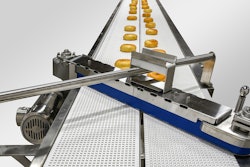

Removing extraneous vegetable matter (EVM), dirt, and other lightweight materials, the Key Technology #16 air cleaner cleans product of debris to improve product quality and line efficiency. The air cleaner features a fan, motor, screen, and chamber configuration to enhance sanitation and reduce maintenance, while increasing airflow capacity and spreading air velocity more evenly across the product screen.Suitable for both wet and dry products, such as peas, green beans, corn, berries, and nuts, the air cleaner removes leaves, steams, husks, dirt, and more. Typically installed at receiving, the system separates EVM and debris early on the production line to improve line efficiency and reduce energy waste. The air cleaner uses positive airflow, which moves through the product as it falls above a diagonal screen, to push light debris up and into a collection hood. It offers airflows up to 538 m³/min (19,000 CFM) depending on the application, and achieves more even distribution of air velocity across the product screen to reliably remove more debris. The stronger, more even air velocity is produced by a smaller fan that operates with the same 20 hp as the previous model to more efficiently meet processors’ product quality standards. The new system has only one moving part, the motor, to reduce maintenance and operating costs. Sanitation has been improved with the elimination of baffling, larger access doors for easy cleaning, and sloped surfaces to help prevent product and moisture buildup. The hinge design has a single lamination, while the screen design includes perforations integrated into the side panels. The fixed twist lock cam latches, eliminating wing nuts. To maximize system performance, Key mounts and integrates each air cleaner with either its dewatering shaker for wet products or its transfer shaker for dry products.

“At Key, we partner closely with customers to develop new solutions to their production problems. Our new air cleaner was driven by one customer’s desire to remove even more debris for a cleaner product. While we designed this system primarily to improve performance, we looked for opportunities to maximize sanitation and maintenance, too,” says Jack Lee, president of Key Technology Americas. “Predictive modeling software was crucial in the development of this air cleaner. Computational fluid dynamics enabled us to model the airflow to put together a revolutionary design backed by real data.”