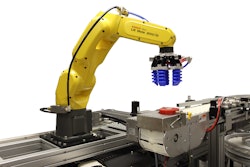

MGS Machine Collaborative Robotic Palletizer

Designed to work alongside humans, the MGS Machine collaborative robotic palletizer eliminates the need for a safety fence; it has a soft foam cover that protects workers who make direct contact. The palletizer handles cases weighing up to 77 lb. at speeds up to 6 cases/min. Anchored by a Fanuc CR-35ia collaborative robot certified to meet all safety requirements for sharing space with people, it offers programming capabilities, end effector tooling and integration services for secondary packaging and end-of-line solutions. The palletizer can be fitted with a variety of end effectors to handle a range of case sizes and styles. Pallet patterns, saved as recipes in the system’s memory, can be recalled to achieve changes in seconds.

Companies in this article