This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

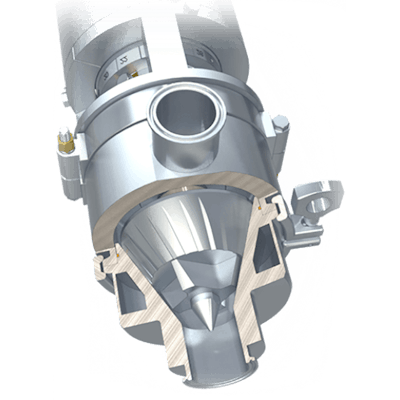

Used for continuous and batch processes, Bematek colloid mills support multiple product milling applications, while meeting particle size reduction requirements. The mills combine a modular design that permits mill chamber interchangeability with various mill heads and a mill chamber that can be rotated 360 degrees to accommodate different piping arrangements. Fine-tuning of applied mechanical shear is achieved through the micrometer-style gap adjustment dial. Heat is removed or added to the units with the mill chamber thermal jacket. The milling chamber has an optional positive stop mechanism that prevents the conical rotor from contacting the stator.