This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

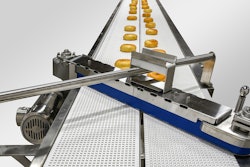

AFC Spiralfeeder flexible screw conveyors feature a choice of spiral types to ensure the screw design promotes efficient material transfer when conveying nearly any type of powder, pellet, flake, or other bulk material. Specified based on the properties of the material to be transferred, the AFC screw conveyors are offered with round, flat, or knife-edge spiral types as standard, along with custom spirals if necessary.

The round spiral shape minimizes friction for transferring sensitive materials, such as coffee beans, with a gentle conveying action on a durable platform for long life and low maintenance. The flat spiral shape acts as a rotating shelf to transfer large volumes of materials with low bulk densities at high flow rates, such as cake mixes. The knife-edge spiral shape is designed to transfer challenging materials that cake, pack, stick, or smear—without clogging the system or degrading the material.

Available on all AFC flexible and solid-screw conveyors, the various spiral types feature carbon-steel or optional stainless-steel construction for sanitary processing, and may be specified in a range of lengths.