This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

The Dorner AquaGard GT infeed and outfeed conveyor is designed for accumulation-type applications to prevent bottlenecks in industries such as packaging, bottling, and dry food processing. All the components (except the motors) are constructed of stainless steel or FDA-approved plastics, which are suitable for operating in environments that require wipe down or occasional washdown cleanings of the conveyor.

The AquaGard GT integrates a range of features and benefits, including powered transfer units, flush side tails, and pre-engineered transfer modules.

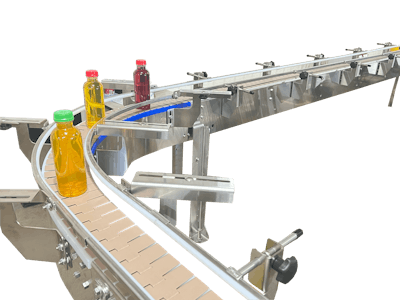

At PACK EXPO Las Vegas, the AquaGard GT will be operating in a fully functional loop with Garvey Infinity and Bi-Flow accumulation tables. The Infinity table accumulates and sorts unstable products at high speeds into a single or multi-lane configuration, while the Bi-Flow table uses opposing conveyor movement to create a buffer for product accumulation in a small footprint.

The loop also includes Dorner FlexMove helix and wedge conveyors, which allow vertical product movement to maximize a smaller footprint.