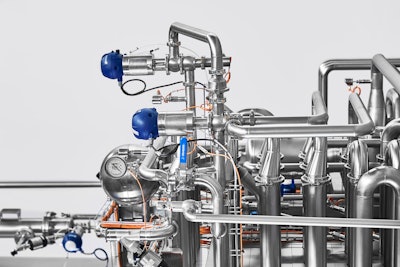

Heat exchangers provide proper pasteurization and allow brands to produce high-quality soups in a large-scale production. HRS Heat Exchangers, a thermal technology and exchanger developer, provides machinery that plays an important role in the production of gazpacho and salmorejo, Spanish soups that require delicate cooking processes.

Gazpacho is a cold tomato soup associated with the Southern region of Andalusia, Spain. It might be less popular overseas than some of Spain’s other culinary imports but is esteemed in its home country. What started as a summer dish for local farmers and their families has gained popularity with the broader Spanish population and tourists due to its refreshing properties and fresh taste.

Demand for gazpacho has driven its commercial production. Large scale modern production began in Murcia, Spain in the 1990s. As such, large suppliers, who often supply heavily pasteurized product in large quantities, and smaller companies, continue to bring gazpacho and salmorejo products to the market.

Salmorejo resembles gazpacho but is thickened with bread. Thus, it is eaten with a spoon from a bowl, while gazpacho is usually drunk as a cold soup. Most manufacturers of gazpacho now also produce salmorejo, according to insight from Francisco Hernández Ortiz, Global Food Projects Director at HRS Heat Exchangers.

Premium gazpacho and salmorejo products are made using good quality fresh vegetables and minimum processing. The soups are often sold as “unprocessed” products with a short shelf life and higher price. In addition, they are often packaged in smaller plastic bottles, which allows consumers to see the product on the shelf.