This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Initially released in October 2019 with oil-based ink capability, the CoPilot Max has the capability to run solvent-based inks, and now UV LED cure inks, allowing users the ability to print on coated corrugate, polystyrene, films, and a number of other non-porous surfaces. UV-based ink is ideal for users looking to replace expensive labels and print directly on glossy cartons, cases, trays, or other substrates without the high maintenance characteristics of solvent-based inks.

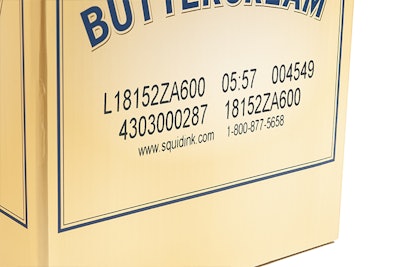

The CoPilot Max utilizes Squid Ink’s revolutionary active ink system, allowing users the ability to raise, lower, tilt, or rotate the printhead without making height adjustments to the ink supply. The system prints hi-resolution characters, razor-sharp text, scannable bar codes, and great looking logos at up to 360 dpi, nearly twice the resolution of competitive printers in its class.

PACK EXPO Connects–November 9-13. Now more than ever, packaging and processing professionals need solutions for a rapidly changing world, and the power of the PACK EXPO brand delivers the decision makers you need to reach. Attendee registration is open now.

The UV LED Curing System from Squid Ink offers accurate and consistent UV curing across a variety of commercial and industrial applications and is capable of curing ink in a 20mm x 80mm illumination area. The system features an advanced LED module that provides consistent luminance, resulting in a reliably cured product every time. The stability of UV LED technology makes the output of electricity predictable and stable, avoiding problems associated with conventional halogen heat lamp drying. Squid UV offers instant on/instant off performance, eliminating warm-up or cool downtimes and streamlining your operation. Best of all, Squid UV LED curing is environmentally friendly, eliminating mercury bulbs, VOCs and providing employees with a safe workplace.

UV LED series inks do not cure without assistance of UV light and require minimal maintenance, resulting in an ideal solution for manufactures looking to mark their non-porous products. Squid Ink’s UV-based inks have superior lightfast properties to reduce fading over time. Designed for permanent marking, UV-based inks provides excellent rub resistance perfect for most non-porous applications.