This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

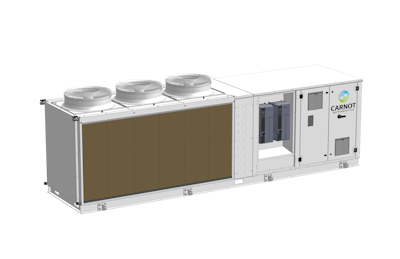

M&M Carnot Aquilon DS CO2 air-cooled condensing units (CDUs) extend the company’s industrial refrigeration product portfolio of transcritical CO2 solutions, which include industrial racks, chillers, heat pumps, and Aquilon DC (data centers) cooling systems.

The high-pressure designed Aquilon DS product line includes fully welded stainless-steel piping, high-pressure compressors, and system components as standard. All Aquilon DS CDUs have fully integrated air-cooled condenser/gas coolers, with an option for adiabatic condensers.

The high standstill pressure design protects against refrigerant (and synthetic oil) releases during system offtime or electrical outages. While the high-pressure design provides a higher level of safety and system availability, it also helps sustain a company’s carbon footprint by eliminating the need for a backup generator.

All Aquilon DS CDUs provide the following energy-efficiency features as standard: EC fans, VFD compressor drives, liquid sub-coolers, and sensible hot-gas defrost. Optional energy-efficiency features include heat recovery and free cooling.

Aquilon DS CDUs range in capacity from 10 to 75 tons, with operating evaporator temperatures from -40 °F to 40 °F for industrial refrigeration and cooling applications that include cold storage/refrigerated warehouses, food processing, dairies, wineries, and data centers.