This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

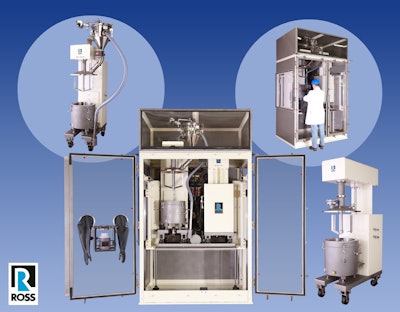

The Ross custom-designed mixing/melting and holding tank system is used to produce highly potent and reactive materials at 350°F and up to 10 psig internal pressure.

The system includes a pressure-rated sealed enclosure with an operator-friendly safety glovebox and two mixers, each equipped with a two-wing anchor agitator, Teflon scrapers, and jacketed 6-gal vessel. One mixer functions as a mixer/melter connected to a vacuum powder loading system; the other functions as a holding tank, which gravity feeds the finished product to a downstream coating machine.

A specially designed elevator system enables the mixers to be lowered to a maintenance position and raised to an operating height, which allows for gravity feed from the melter to the holding tank.