This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

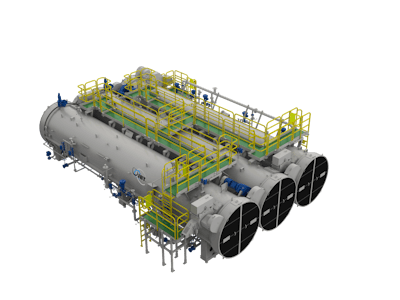

The JBT 2.1m pressure rotary sterilizer provides improved product quality and consistency at a lower cost per unit produced. It provides the features and benefits of the standard sterilizer, however, a larger diameter offers an increase in production throughput from 25% to 50% compared to the 58-in. pressure rotary with approximately the same floor space.

The sterilizer can handle a range of cans, allowing for high-temperature/short time (HTST) cooking and rapid, efficient cooling by agitating the container in an automatic, continuous process. This ultimately allows for fewer resources and utility consumption per can while increasing the throughput.

The new sterilizer allows the consolidation a number of existing rotary sterilizers into one high-capacity 2.1m rotary. For most applications, the existing 58-in. rotary thermal process will not change when upgrading to the 2.1m rotary.

The 2.1m sterilizer:

- Reduces water and energy consumption

- Offers lower maintenance and longer machine life

- Provides higher throughput in the same footprint

- Uses fewer resources per can produced