This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

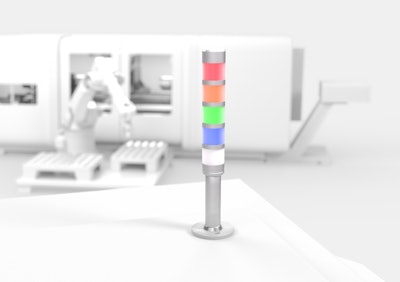

Leuze TL 305-IOL tower lights with IO-Link interface make states, faults, and ongoing processes clearly visible from a distance, enabling optimum signaling at the machine, on the conveyor belt, or for access control. The tower lights offer different operating modes and come in a range of colors.

The segment mode enables the segments to be actuated individually via IO-Link, allowing color, intensity, and lighting sequences to be configured individually, while the level mode is used to visualize fill levels.

The TL 305-IOL tower lights can be parameterized flexibly via the IO-Link interface. System operators can signal individual machine states by means of different brightness levels, lighting sequences, colors, or types of signal sound.

If fast commissioning is required, eight predetermined or user-defined configurations can be actuated via the three external inputs, even without IO-Link connection. The M30 thread and M12 connector make the lights easy to install. Matching accessories simplify installation.