This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Process equipment manufacturer Gericke USA, Somerset, NJ, has unveiled dosing software that automatically verifies the accuracy of gravimetric bulk material feeders.

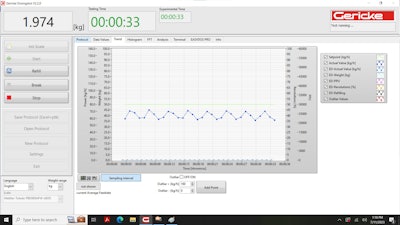

Developed to provide independent validation of feeder sensor data, the Gericke Dosingtest V2.2 measures, records, and analyzes mass flow data of powders, granules and other bulk materials in real time to reveal any differences between sensor data and actual production, or to confirm the validity of sensor data. Once a discrepancy is revealed, action may be taken to determine the source of the discrepancy and restore the feeder to the proper settings.

Ideal for food, chemical, pharmaceutical, and other manufacturers requiring verifiably precise feeding and dosing, the Gericke Dosingtest V2.2 also provides the comprehensive documentation required to comply with FDA, USDA, and OSHA data integrity regulations, ISO certifications, and other industry standards, directives, and requirements. Material weight, bulk density, overrun weight, doser revolutions, number of refillings per hour, and other parameters can be documented and analyzed using a variety of interactive graphs and charts.

Offered as an option on the company's Feedos S and Feedos M loss-in-weight feeders, the feeder validation software operates on a PC linked with a feeder dosing into a container set on a check scale. The precision feeding system may be tested on fully operating equipment in the company's New Jersey test laboratory.