This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

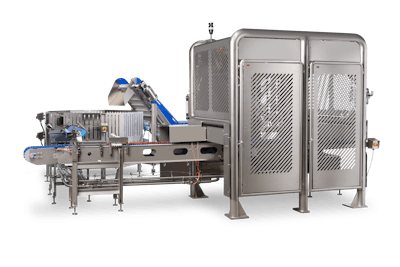

JLS Automation is set to debut the Kestrel™, a high-speed hygienic robotic collate and load system.

The Kestrel combines precision, speed and versatility in a compact footprint. It is specifically engineered to handle uniform, cylindrical food products such as meat snack sticks and straight sausages.

At the heart of the system is high-speed centrifugal technology that singulates products from bulk infeed with remarkable accuracy. This is a process that is traditionally complex, using conveyor belts with rails or lane dividers that guide products into rows. This process often results in tumbling or bottlenecks, requiring manual intervention. Since products often need to be gently guided into position on these traditional systems, throughput is typically lower. The friction and mechanical contact can also damage delicate product surfaces.

JLS Automation

JLS Automation

To overcome these challenges, the Kestrel feeds products onto a custom collation conveyor that precisely aligns them for robotic gang-picking, consolidating processes, and reducing wear parts. A hygienic delta kinematics robot then picks and loads collated products directly into thermoformer pockets or other primary packaging formats. With the Kestrel, protein manufacturers achieve higher yield, reduced dependency on manual labor and gain consistent presentation without compromising product integrity.

"The Kestrel represents a transformative solution for protein processors facing unprecedented labor challenges and the need for increased efficiency," said Waheed Chaudhry, Director of Primary Packaging, at JLS Automation. "By automating the traditionally complex bulk-to-packaging process with hygienic design principles, we're enabling our customers to scale production while maintaining the highest food safety standards. This system sets a new benchmark for what's possible in high-speed collate and load technology."