Food manufacturers and ingredient suppliers have access to a wide range of high-tech milling methods. Each one offers advantages for achieving product characteristics such as particle size and moisture content, along with other considerations such as cost, footprint and the need for ancillary equipment. Each method has also given rise to a diverse range of size reduction equipment. In fact, there may be more than one solution when selecting milling equipment.

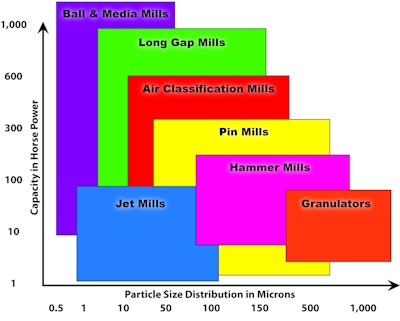

According to Suha Ozsoylu, director of operations at Hosokawa Micron Powder Systems, the most important step in selecting size reduction equipment is establishing the target size reduction of the end product. This target is typically based on the particle size and particle size distribution desired, typically expressed in terms of milling the material down to a given particle size distribution in microns. "End products that demand the vast majority of particles consistently measure the same size. For example, cake flour, often requires a different approach to milling than end products that include a range of different sizes, such as cookie crumb or chopped walnuts. The particle size directly affects the amount of surface area and the interactions among the flour, water and other ingredients. For cakes and other baked goods to achieve a desired delicate, heavy or fluffy texture every time, the baker needs the flour to meet the same particle size every time."

Testing and particle size analysis

Despite the importance of determining the required particle size, many product developers do not know the size of their existing products or the particle size needed for new products, says Ozsoylu. When asked about the target particle size, “something like flour,” “as fine as possible” or “just like cereal” are common responses, he adds. In these cases, develops should consider checking with a milling machinery manufacturer that has a track record with the product. Identifying systems that are proven to work with a given product can accelerate the specification process by weeks or months.

Whether the product matches existing test data or you are starting from scratch, today's milling equipment manufacturers offer configurations and custom options that can meet tight specifications. Testing the actual product on lab-size and/or full-size machinery is recommended. The first step in testing often involves evaluating a sample on a particle size analyzer that uses pneumatic sieving to determine the particle size distribution and provides a target end point. Other product characteristics can be addressed such as the size at the infeed, bulk density, flowability, hardness, moisture content, heat sensitivity, toxicity and even explosivity.

Milling selection: Hammer and screen mill

Check to see if a low-cost technology can meet the requirements, Ozsoylu suggests. One of the least costly types of milling machinery for food products is also the most frequently used. The hammer and screen mill style uses the impact of swinging hammers that rotate at high speeds inside a round housing to reduce the particle size. When the particles meet the targeted size, they fall through a screen and into collection. Screens are available in a variety of sizes and configurations to suit dry, sticky, fibrous or abrasive ingredients. Today's most effective hammer mills grind down to D90 <75 µm. If a finer end product is required, a more advanced impact systems may be considered.

Pins, knife and attrition mills

Advanced systems achieve fine grinding down to D97 <35 µm. They replace the hammer rotor with a pin disc style rotor and force the material to collide with a series of pins set in concentric circles protruding from high-speed rotating discs. This style excels in milling crystalline, fatty and oily products such as spices that may buildup and blind screens. The latest models allow these fatty, oily and other heat-sensitive products to be processed without separate cooling equipment.

Other systems replace the hammers with knife rotors that granulate the material. These perform well for coarse granulation to medium fine size reduction and excel with softer products.

For finer milling of soft and/or heat-sensitive products, attrition mills offer an alternative. These mills grind the product between two, tapered plates that rotate at high speeds, reducing the particle size as the product moves from the infeed at the center to the periphery for discharge and collection.

Air classifying mills

When the target demands very narrow particle size distributions with grinding down to D97 at <20 µm, air classification mills may be considered. Bringing a higher level of engineering to the process, the latest air classification mills combine impact milling with dynamic air classification. Material is fed from a silo or fed into the hopper and automatically conveyed first into a milling chamber where hammers rotate at high speeds for size reduction.

In this design, particles are constantly recirculated from the outer liner back into the rotating hammers. When the particles meet the desired size, air carries them to an internal classifier. On-spec particles exit the mill for collection, and any oversized particles are rejected and captured for further milling.

"Air classifying mills can reduce very large particles such as 6 mm grains of rice to very small particles under 50 µm in a single pass with minimal fines when other mills would take several passes," says Ozsoylu. This type of mill is quickly becoming the preferred system for companies that focus on efficiency and lean operations, he adds. "Its easy-to-clean design and flexibility for processing multiple products on the same system make it a good choice for the food processing industry."

Other types of milling equipment such as traditional ball mills and advanced fluidized jet mills perform similar ultra-fine size reduction, but rarely offer the same combination of capabilities and low cost for processing food products, states Ozsoylu

Making the right call

More than one of the systems described may effectively meet the target specifications. Initial cost must be considered, along with secondary factors such as footprint, maintenance needs and versatility. In many cases, the initial cost needs to be weighed against the gains in product quality, production speed, dust control and worker safety along with energy savings and the payback period.

With numerous milling options available, food processors face a challenging landscape when sifting through the range of methods and machines. Further, many mills require an array of ancillary components upstream and downstream of the actual mill from storage silos and feeders to conveyors and dust collectors. In these cases, consider whether the milling equipment manufacturer has experience integrating all of the elements as an integrated mill system.

Resources:

https://www.youtube.com/user/HosokawaMicron/videos.