According to Busch Vacuum Solutions’ Uli Merkle of global marketing department, “Freeze drying is a modern extension of traditional drying methods to protect food from spoilage for longer periods of time. This process is only made possible by modern vacuum technology because freeze drying food takes place under vacuum.”

While soluble (instant) coffee is probably the most well-known freeze-dried product, freeze drying is also suitable for fruit and berries as well as for cooked meat or vegetables. Herbs and spices are also preserved through freeze drying by removing all but a few percent of the water from these products. Says Merkle, “During freeze drying, the structure of the food remains unchanged and the dried cells can easily absorb water again during preparation. By drying under vacuum, the aromas are largely preserved.”

The process

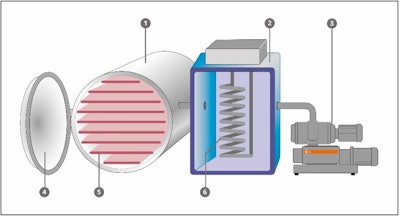

Freeze drying (Fig. 1) is a physical process that uses the principle of sublimation. Due to the vacuum in the drying chamber, the frozen water sublimates into water vapor. The ice skips the "liquid" state and becomes directly "gaseous" from "solid."

Fig. 1: Schematic representation of a freeze dryer: 1. Drying chamber, 2. Condenser (cold trap), 3. Vacuum system, 4. Opening gate, 5. Heatable intermediate plates, 6. Cooling coil. Image courtesy of Busch Vacuum Solutions.

Fig. 1: Schematic representation of a freeze dryer: 1. Drying chamber, 2. Condenser (cold trap), 3. Vacuum system, 4. Opening gate, 5. Heatable intermediate plates, 6. Cooling coil. Image courtesy of Busch Vacuum Solutions.

Before the actual drying process, the product must be spread over trays inside a cooling chamber to deep-freeze. The frozen product is then placed in the actual drying chamber (Fig. 2). Though, in some freeze dryers, cooling takes place directly in the drying chamber. Freeze dryers for continuous processes are also used in food processing.

“After cooling, the drying process takes place in the air-tight chamber by reducing the air pressure via a vacuum pump until a vacuum of 1 to 0.5 mbar is reached,” says Merkle. “The evaporation process of the frozen water then starts at -58 to -40° F. The water vapor is suctioned out of the drying chamber by the vacuum pump into a downstream condenser. In this "ice trap" cooled to at least -94° F, the water vapor sublimates and condenses as ice on the cooling coil. Most of the moisture is removed from the product in this process step, called primary drying.”

Caption: Fig: 2: Two drying chambers are operated in parallel at a manufacturer of freeze-dried foodstuffs. Image courtesy of Busch Vacuum Solutions.

Caption: Fig: 2: Two drying chambers are operated in parallel at a manufacturer of freeze-dried foodstuffs. Image courtesy of Busch Vacuum Solutions.

During sublimation, thermal energy is extracted from the drying chamber, dropping the temperature during this part of the process. To heat the chamber, only as much thermal energy is added as is taken from the water as sublimation energy, in order to keep the temperature constant or allow a slight increase in temperature up to -4° Fahrenheit.

For most foodstuffs, primary drying is immediately followed by secondary drying. This involves removing more strongly bound residual moisture from the product by lowering the vacuum level to 0.01 mbar or below and raising the temperature above the freezing point. The drying chamber is then ventilated to atmospheric pressure, and the dried product with a water content of one to four percent is removed for further processing. Dry air or an inert gas is used for ventilation so that the dried product cannot absorb moisture from the ambient air.

Physical parameters

The freeze drying process essentially depends on these parameters (Fig. 3):

- Pressures, or vacuum levels

- Temperatures

- Time

Though, the products and their properties also have an effect, so trials are to be carried out in pilot plants before industrial freeze drying or before drying large quantities of product.

Fig. 3: Process of freeze drying. Image courtesy of Busch Vacuum Solutions.

Fig. 3: Process of freeze drying. Image courtesy of Busch Vacuum Solutions.

Vacuum technology

Busch Vacuum Solutions offers two types of industrial vacuum systems:

Which vacuum systems is more suitable depends on the size of the drying plant, the products to be dried, and the physical parameters already mentioned, says Merkle.

Vacuum system with rotary vane vacuum pumps and vacuum booster

Rotary vane vacuum pumps are oil-lubricated and reach an ultimate pressure of up to 0.1 millibar. In order to generate a higher vacuum level and to have a sufficiently high pumping speed in the working range of less than 1 millibar, the company advizes using a vacuum booster. A combination of a rotary vane vacuum pump and vacuum booster can be designed to the size of the freeze dryer and is more energy efficient than a large single rotary vane vacuum pump. “This technology offers excellent ease of use, and has proven its performance and reliability for over 50 plus years of service in industrial applications” said Geoffrey Cresswell, Busch product manager.

Fig: 4: A standard system from Busch Vacuum Solutions includes an R5 rotary vane vacuum pump as backing pump and a PANDA vacuum booster. Image courtesy of Busch Vacuum Solutions.

Fig: 4: A standard system from Busch Vacuum Solutions includes an R5 rotary vane vacuum pump as backing pump and a PANDA vacuum booster. Image courtesy of Busch Vacuum Solutions.

Vacuum system with screw vacuum pumps and vacuum booster

Screw vacuum pumps operate dry (in other words, oil free) and achieve an ultimate pressure of up to 0.01 millibar. According Teo Cusmina, Busch US product manager, "The main advantage is the dry compression; no contamination or reaction is possible between process gas and operating fluid. Eliminating the oil means low maintenance and longer service intervals which results in less repairs and less cost." Also, a vacuum system with a screw vacuum pump along with a vacuum booster is a preferable system to single vacuum pump, according to Merkle. “Screw vacuum pumps can be equipped with a frequency-controlled motor so that the pumping speed automatically adapts to the respective requirements of the process step during freeze drying,” he says.

Fig. 5: A standard system from Busch Vacuum Solutions has a COBRA screw vacuum pump as backing pump and a PANDA vacuum booster. Image courtesy of Busch Vacuum Solutions.

Fig. 5: A standard system from Busch Vacuum Solutions has a COBRA screw vacuum pump as backing pump and a PANDA vacuum booster. Image courtesy of Busch Vacuum Solutions.