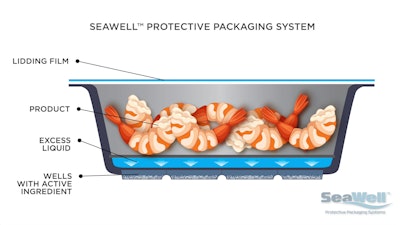

Aptar Food + Beverage intends to enhance the freshness of packaged seafood from sea to table with its latest active packaging system. The Crystal Lake, Ill.-based company developed SeaWell, packaging designed to separate seafood from excess liquid in order to mitigate microbial growth, pre-vent breakdown of the product, and extend shelf life.

SeaWell features integrated technology that absorbs excess liquid that would otherwise accumulate around the seafood. The packaging consists of a tray made out of recyclable PP with cavities at the bottom. A proprietary blend of direct food-contact-safe powder is placed in the cavities and secured with a nonwoven fabric heat-sealed over the cavities. The powder, which is GRAS (generally recognized as safe) certified by FDA, absorbs excess liquid that the sea-food releases and traps the liquid in the wells of the tray, keeping the liquid away from the seafood. The company also makes a pouch version of SeaWell, in which pillow pockets in the back of the pouch contain the powder. They are typically used to package odd-shaped seafood, such as crab legs or whole fish. The packaging is available in a variety of sizes for retail and foodservice.

Reeling in results

Because SeaWell prevents the seafood product from sitting in excess liquid, the packaging reduces the rate of microbial growth and chemical degradation. According to the studies Aptar has conducted, SeaWell averages a 1-log (90%) reduction in bacteria.

In addition to absorbing odor and maintaining the product’s visual appeal, SeaWell also extends the shelf life of the seafood product compared to foam trays with diaper pads and plastic overwraps, bucket packaging, net bags, and other traditional seafood packaging. For example, Aptar says SeaWell packaging can increase the shelf life of mussels by 15% and oysters by 70%. SeaWell can also extend the shelf life of lobster meat by four days and fish roe by 5 days, according to the company.