This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

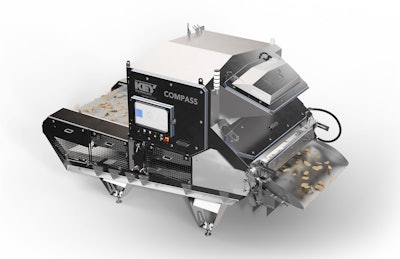

Key Technology (Key), a member of Duravant’s Food Sorting and Handling Group, introduces its COMPASS® optical sorter for chips at PACK EXPO Las Vegas Booth W-1040. Designed specifically for potato chips, tortilla chips and similar snack foods, this belt-fed sorting system identifies and removes product defects and foreign material (FM) to protect food safety and product quality. Delivering sustained performance over long production cycles with minimal human intervention, COMPASS simplifies operation, cleaning and maintenance while providing a quick return on investment.

“Key has been at the forefront of potato chip sorting and handling technology for decades, and COMPASS represents the next evolution in our commitment to this industry,” said Jack Lee, Duravant Group President - Food Sorting and Handling. “We’ve leveraged our extensive applications expertise to develop innovations that address the real operational challenges of chip processors, including automatic belt tracking, intuitive controls and clean-in-place features for extended run times between sanitation cycles.”

COMPASS improves routine operation with recipe-driven programming and a user interface designed to mimic smartphone app navigation. Operators can easily create and adjust sort recipes, including adding new products to sort, new grades or different varieties of an existing product. A new operator without any technical skills can learn how to operate the system in production in as little as 30 minutes. Intelligent belt control automatically maintains proper tracking, including compensating for belts that have either stretched or shrunk, to reduce downtime and manual adjustments.

Powered by Key's advanced NEXT sort engine, COMPASS detects and rejects product defects such as, dark spots, green discoloration and white knot bruises, along with FM like fryer debris. Equipped with customizable camera options and up to 8 channels of multispectral sensor data, the sorter can detect the color, size, shape and structural properties of every object to identify more, smaller defects than systems with conventional 3-channel cameras.

Designed for maximum sanitation, COMPASS features open architecture, sloped surfaces and minimal moving parts. Sensors and light windows are positioned away from product splatter, and stain-resistant belt technology helps sustain accurate inspection throughout long production runs. Specialized collection systems, including counter-rotating brushes or scrapers, direct oil and chip debris into easily removable bins for safe, efficient disposal. The belt can be quickly removed for thorough cleaning, while the open design allows easy access for workers and reduces cleaning and maintenance requirements. Washdowns can be completed in as little as 15 minutes.

Every COMPASS is equipped with Key Discovery™, a powerful data analytics and reporting software that turns the sorter into an IIoT-connected device and information center. By delivering detailed product quality and sorting process data, Key Discovery gives processors valuable insights into line operations, quality trends and opportunities to optimize upstream processes like fryer settings.

COMPASS is available in multiple configurations to meet individual application and capacity requirements, including the ability to integrate Key's high-performance infeed and discharge conveyors for complete system solutions. Beyond traditional chip applications, this belt-fed COMPASS can handle other snack products including extruded snacks, pellets and specialty items like sesame sticks.

Key supports its customers worldwide through an extensive sales network and its global service team. For more information on Key’s optical sorters, visit www.key.net/en/our-products/sorting/.