Though pasteurization has been shown repeatedly to effectively kill pathogens in milk—a point that has been brought up often as more consumers jump on the raw milk bandwagon—there are some strains of bacteria that can withstand heat treatments, giving them the potential to induce foodborne illness. To help minimize and predict the magnitude of this risk, a team of researchers has developed a model that can guide processors to improve food safety.

The most common method of pasteurizing milk in the U.S. today is high-temperature, short-time (HTST) pasteurization. In a recent issue of the Journal of Dairy Science, the researchers describe the model they’ve developed to assess that method and how it might expose consumers to pathogenic Bacillus cereus group organisms, closely related species categorized into eight phylogenetic groups.

“The Bacillus cereus group is a diverse group of microorganisms in terms of their implications on food spoilage and safety,” says team leader Jasna Kovac, Lester Earl and Veronica Casida Career Development Professor of Food Safety in the College of Agricultural Sciences at Penn State. “The novelty of our study is in generating experimental growth data and models for different genotypes, or genetic makeups, of toxin-producing B. cereus group strains. Our approach to elucidate differences in the growth potential of various genotypes in milk allowed us to develop a more accurate exposure-assessment model.”

Assessing the risk along the cold chain

Although B. cereus group organisms generally produce mild, short-lived symptoms, they are common biological hazards along the dairy production chain that often persist in biofilms within the dairy processing environment. This is particularly relevant when considering an often inefficient cold chain—which can be subject to increases in temperature in refrigerated trucks, consumer transportation from the store, and inappropriate home storage.

The model that the researchers have developed make it much easier to determine the level of risk in any given milk sample. Processors test the milk to determine which strains of B. cereus group bacteria and how much might contaminate the product. They can feed that information into the model to predict if a contaminant is likely to grow to a high level in a large proportion of produced food units, resulting in high-risk exposure of many customers.

| Federal Government Pledges Close to $200M to Stop Spread of Avian Flu |

Foods contaminated with 100,000 cells per milliliter of B. cereus group microorganisms have been linked to foodborne illness, Kovac notes. In the model developed in this study, some genotypes were predicted to grow to 100,000 cells per milliliter of milk, but the concentration per simulated milk container could vary from very low levels of bacteria to 10 times more. “This is significant because this difference in exposure can be translated to different levels of risk for foodborne illness,” she says.

In the study, researchers measured the growth, in skim milk, of 17 toxin-producing B. cereus strains across the gene profiles of six related bacteria groups with various virulence, or ability to cause disease. The strains did not grow in HTST pasteurized milk at 39°F or 43°F; at 46°F, one strain grew; at 50°F, 15 strains grew; and all strains grew at temperatures of 57°F or above.

Using this growth data, the researchers developed secondary growth models and the exposure-assessment model. This model, focusing on the HTST pasteurized milk supply chain and up to 35 days of consumer storage, with an initial contamination of 100 cells per milliliter, estimated that 2.8% of milk containers would surpass potentially dangerous levels of B. cereus group bacteria by day 21 and 4.1% would by day 35.

Next development steps

“I believe that this tool can provide a valuable decision-support system for dairy companies, particularly if food safety systems continue to move toward a truly risk-based approach that accepts that zero risk is not possible,” says Martin Wiedmann, research team member and professor of food safety and food science at Cornell University. “In addition, I believe that other food industry sectors may adapt this tool to provide decision-making support in other types of food products."

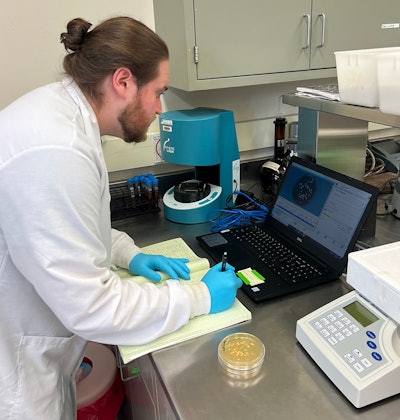

Study co-first author Jun Su, doctoral student in food science at Cornell University, develops an exposure-assessment model.Cornell University

Study co-first author Jun Su, doctoral student in food science at Cornell University, develops an exposure-assessment model.Cornell University

The next step in the research is aimed at making this new technology accessible to the dairy industry. The researchers are now working on integrating this model into an open-access application that will be available for milk processors to use, Kovac says.

| Dairy Processors Weigh in on Sustainability of Farms |

“We are working on a system in which a user can enter the concentration of bacteria detected in milk and upload the information about the genotype,” says Jun Su, co-first author of this study. She is a doctoral student in food science working in Wiedmann’s research group at Cornell. “That will produce a prediction of what percentage of milk containers likely will carry B. cereus exceeding the concentration that has previously been linked to foodborne illness.”

That prediction is based on results generated by this research, according to Tyler Chandross-Cohen, co-first author of the study. He is a doctoral candidate in food science working in Kovac’s research group at Penn State. “Our data quantifies the ability of different genotypes of Bacillus cereus group bacteria to grow at various temperatures, as well as their ability to produce toxins that make people sick,” he says.

Also contributing to this research were Kayla Kimble and Mackenna Yount, food science graduate students at Penn State; Chenhao Qian, Department of Food Science, Cornell University; and Laura Carroll at Umeå University in Sweden.

The U.S. Department of Agriculture’s National Institute of Food and Agriculture funded the research.