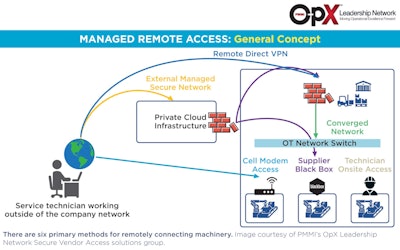

Threats to plant information networks and interconnected machinery can have a negative impact on productivity for food and beverage manufacturers. PMMI’s OpX Leadership Network has created a Secure Vendor Access solutions group that helps both processors and equipment manufacturers understand the risks and rewards of remotely connected processing and packaging machinery. The group’s goal is to enable safe remote diagnostics and assistance by the equipment suppliers in CPG manufacturing plants.

The OpX solutions group has created a Best Value Options Analysis to enable transparent, nontechnical discussion of the pros and cons of each of the primary methods for connecting remotely. The Best Value Options Analysis includes the skills required to implement and maintain secure access, the cost to acquire and operate it, and an overall value proposition. The analysis covers the following primary methods for connecting remotely:

- Direct VNP.

- Converged network.

- Cell modem.

- Black box.

- Technician.

- External managed secure network.

“In past experiences, IT and engineering were two isolated departments that didn’t work well with each other,” says OpX solution group participant Robert Dargie, an electrical engineer with Amway. “You’ve got to develop a partnership between the two departments to develop some of these standards.”