In addition to its familiar competencies in filling, processing, and packaging equipment, Bosch Packaging Technology offers packaging solutions to cargo and bulk materials companies in the food industry. In this space, a chief concern is maintaining consistent, uncompromised quality in sensitive products, namely whole bean or ground coffee. But in the process of packaging such products, important characteristics like aroma are prone to be adversely affected.

So Bosch developed the VIS flavor protection valve to protect the flavor of the packaged coffee, even after prolonged storage. This VIS valve, installed inside the bag in this case, permits degassing into the environment. The valve also prevents external oxygen, which can compromise coffee quality and aroma, from entering the package.

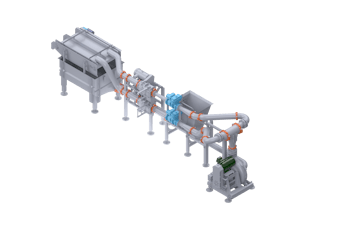

To apply this valve into film, the company developed its CVA VIS valve applicator machine. Running with an output of as many as 120 valves/min on film as wide as 500 mm, this intermittent-motion machine can stand alone or can be integrated into a number of Bosch f/f/s machines to feed “valved” film into the f/f/s for coffee filling and sealing applications like this one.

But how do you install these highly functional VIS valves inside the bags without compromising the bags’ appearance? Bosch needed an alternative to the heat-sealing method it had been using, so it engaged Emerson’s Branson Ultrasonics to ensure the CVA VIS was up to this task. The most important production requirement for the VIS valve applicator was to find a welding technology that would ensure a secure connection between the valve and the bag film with high weld repeatability and consistent valve function. The requirement for rapid cycle times further complicated matters.

The Branson team got involved in the early development of the application, starting with material selection, weld-seam design on the valve base body, and design of the ultrasonic sealing tools and sealing station. The result was a Branson ultrasonic system that features a DCX A power supply, a 40kHz stack, and a 4TP converter. It provided the weld repeatability, process monitoring, and long service life required of all the system components. Its 40kHz technology was able to produce a tight weld, even when diverse types of packaging materials were used. And unlike the previous heat-sealing method, the DCX ultrasonic technology did not interfere with the valve function, and it provided a weld process that operated reliably, with flexibility and rapid cycle speed to help keep the unit costs per bag economical.

“Bosch appreciates Emerson’s high degree of reliability and anticipates the long-term, future-oriented partnership,” said Alden Schiavi, North American Sales Manager, Coffee, at Bosch Packaging Technology.