This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Vanmark, an industrial potato and produce processing equipment manufacturer, announced its Helix Hydrocutting System, designed to help curly fry producers achieve high volume with maximum results and yield.

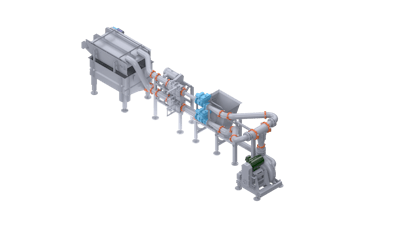

The system uses twin cutting heads in a stacked configuration that allows for increased throughput, a single point of access to the heads, and a moderate footprint. Designs can scale from two to 12 or more cutters to maximize production. The hydrocutter replaces mechanical cutters, offering ease of maintenance with toolless blade changeouts and annual rebuild service by Vanmark technicians.

“Vanmark has been the global leader in food hydrocutting equipment for decades, used by leading industrial food processors to cut potatoes into a variety of shapes and sizes,” says Jason Davis, Vice President, Vanmark. “The Helix Hydrocutting System brings that expertise into a spiral cutting machine that consistently and efficiently slices curly fries to meet the demand in this high-value product market.”

The Helix Hydrocutter features:

- High-volume throughput of 5,000 lbs/hr (2268 kg) per cutter

- Up to 92% sellable product

- A range of system configurations, from 2-12+ cutters stacked for a moderate footprint and mounted to a cutting deck or floor

- The complete system includes a pump, distributor, cutters, and dewatering conveyor

- Maintenance-friendly with patent-pending toolless blade changeouts and an annual rebuild service

- Integrated central control system

- Vision system

Vanmark’s Helix Hydrocutting System is available now. Learn more here.