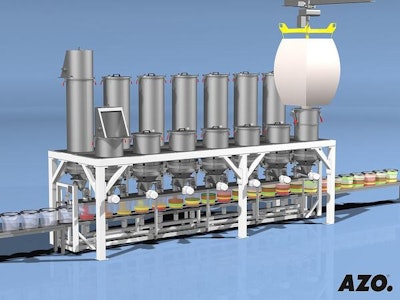

AZO COMPONENTER Step system

At PACK EXPO Las Vegas, AZO (azo.com) introduced its COMPONENTER Step system, which automatically weighs minor and micro components, such as pigments, colorings, flavoring agents and additives, with gram accuracy. The components are held ready in raw material storages on the upper level of the system, where they are identified using the barcode and allocated to the correct hoppers. After product is dosed, a target container positioned below the dosing point is transported to the next dosing point. Target containers are tracked using identification technology and are monitored throughout the weighing and metering process. Separate scales are provided for each component.

Companies in this article