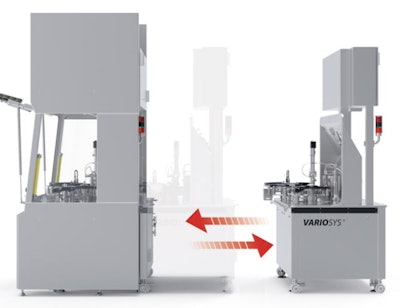

The VarioSys® production system is essentially a combination of two elements: an isolator made by SKAN and machine modules made by Bausch+Ströbel or Harro Höfliger. The system optimizes flexibility in the production of medications because multiple filling modules can be wheeled in and out of the SKANisolator. The machine modules are simply rolled into place on the "lock-and-key" principle and plugged in.

“Before this kind of system was available a pharmaceutical manufacturer was required to dedicate one isolator and one filler to each container style, from syringe to vial to ampule to cartridge to I.V.bag,” says Bausch & Stroebel Sales Group Leader Frank Haerterich. With VarioSys® that’s no longer necessary. The same Skan isolator accommodates multiple filling machine modules. And pharmaceutical production can be extended even further by adding a suitable freeze-dryer made by GEA.