Film manufacturers that produce packaging materials for plastic bags and packaged goods are demanding increased impact/puncture strength for product integrity during packaging and transport. Now, they can validate the film’s strength using a new impact testing tool recently introduced by materials testing company Testing Machines, Inc. (TMI).

The Spencer Impact Tester attachment has just been released as an available option on TMI’s Elmendorf Tear Tester, model 83-76. It can either be purchased integrally with a new 83-76, or added later, providing additional utility from this widely used tear testing instrument.

Impact resistance of plastic films provides useful information to determine the energy required to puncture a film sheet. The Spencer Impact method is based on ASTM D 3420. An attachment to the Elmendorf Tear Tester is mounted on the top of the instrument and measures the puncture impact resistance of a plastic film sheet or other related sheet-like material.

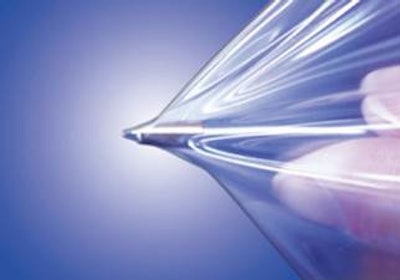

The fixture consists of a probe mounted onto the end of the Elmendorf pendulum and an air-operated clamp used to secure the film sample. The unit measures the resistance to impact/puncture as the probe penetrates a sheet of plastic film. Both Elmendorf Tear and Spencer Impact measurements can be performed on one instrument.