The system helps manufacturers extend shelf life, prevent costly recalls and returns and reduce waste.

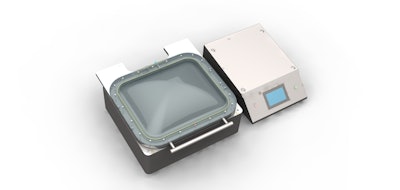

The S600 model relies on a proprietary differential pressure method to detect both gross and fine leaks and offers a faster, easier and quantifiable alternative to methodologies like water baths and gas-based testing. With the new test chamber, food manufacturers can increase efficiencies by testing multiple products at the same time. The Contura® S600 is ideal for a variety of food applications including pet food, meat and poultry, baked goods, snack foods, confectionery/candy, cheese, grains and cereals, prepared food and produce.

“Identifying package leaks, however big or small, is a necessity for food manufacturers looking to catch faulty packages before they make it to store shelves,” said Bill Burnard, Package Integrity Sales & Business Development Manager, North America, Inficon. “As bulk and oversized packages continue to proliferate the market, the Contura® S600 gives manufacturers additional flexibility to test their large size products and protect food quality, enhance safety and maximize consumer satisfaction. The addition of the S600 to the Contura® family also ensures that Inficon is well-equipped to meet the varying needs of today’s food manufacturers.”