This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Hapman’s tubular drag chain conveyor smoothly conveys blended materials from the mixer without separation. The engineered distance between flights in the chain assembly provides optimum conveyance while mitigating material flowability, thus preventing the separation of the blended material.

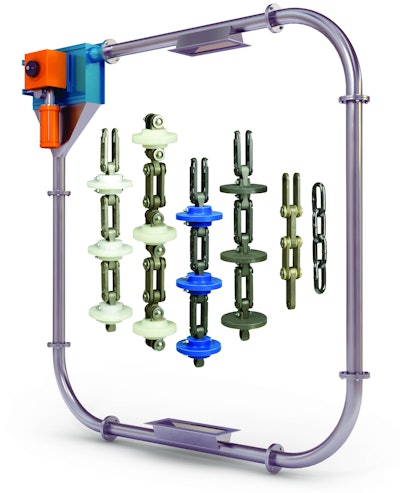

Hapman’s tubular drag conveyor is a versatile choice for bulk solids handling, easily conveying on multiple planes and in any direction from numerous inlets and outlets. The flexible engineered design allows for infinite layout configurations to efficiently convey a variety of materials beneath floors, around doors and plant obstacles, and through walls and ceilings. A heavy-duty chain and flight design results in gentle, quiet performance with little need of service. Hapman’s tubular drag conveyor has successfully handled a diverse range of materials, from hardened steel shot to pasta. Comes with Hapman’s exclusive Performantee™, a true performance guarantee.

The chain-driven flight mechanism offers a number of benefits, including:

• Gently conveys friable and blended materials

• Dust-free operation eliminates toxic or flammable spillage, odors and

airborne dust that creates hazardous work areas

• Protects material from outside contamination

• Flexibility of system layout - conveys horizontally, vertically, at any angle

and around corners

• Complete discharge of material

• Starts under load

• Low operating costs

• Accommodates multiple inlets and outlets

• Large capacity up to 50 CFM