This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

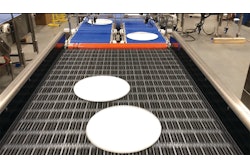

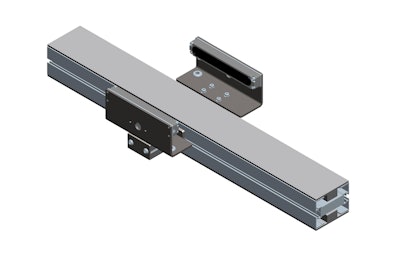

Dorner's clamping module option for conveyors is ideal for totes, boxes, bottles, and square, round, and rectangular containers. As products pass through the clamping module, pre-programmed photo sensors trigger a pneumatic-clamping actuator that is mounted on both sides of the conveyor. The clamping module produces a gap of about one product length; product must be able to withstand some back pressure and squeezing force.

Features and technical specifications of the clamping module include:

• Maximum single product weight: 2.3 Kg (5 lb)

• Maximum product accumulation weight: 13.6 Kg (30 lb)

• Fixed or adjustable width Clamping Module option

• Maximum conveyor speed: 50 m/min (164 fpm)

• Mounting for photo sensor with 18 mm barrel

• Available on FlexMove conveyors:

• FS (65 mm)

• FM (85 mm)

• FC (105 mm)

• FL (150 mm)

• FU (180 mm)

• FV (260 mm)

Information to know at time of order includes conveyor width, product width and centerline of clamping actuator above conveyor chain.