This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

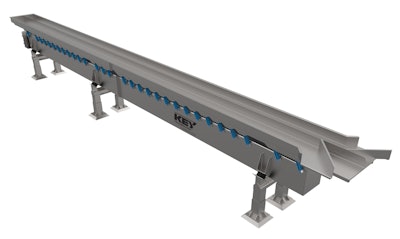

Available in lengths from 30 to 50 ft and 20- to 40-in. widths, the Key Marathon vibratory conveyor with monobeam construction uses natural-frequency vibratory motion to distribute bulk foods long distances at speeds greater than 50 ft/min. The sloped frame and spring arms are positioned underneath the bed, enabling workers to get closer to the stainless-steel bed, which can be tilted to draw product to one side; flow direction can be controlled with optional side outlet diverters. The conveyor can be used for a range of bulk food applications, from raw receiving to packaging, and comes in four finishing standards.

See us at PACK EXPO Booth C-4225