This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Certain applications, such as in jig construction, automation systems or testing systems, require moving elements supported by extremely precise bearings. The JW Winco GN 7580 precision hinges offer the long service life and adjustability, to keep your project running smoothly.

The GN 7580 family consists of three size variants, each with four inner and outer leaf types. The leaves differ in turn by the type of mounting, which can be tangential or radial and make use of countersunk cylindrical bores or integrated threaded bushings of stainless steel. Plus, JW Winco put thought into ensuring simple and positionally accurate mounting - the fitting bores ensure exact positioning of the hinges during installation.

The four-leaf types are designed to be mutually compatible and can be used together as needed in any combination – to cover a wide range of applications.

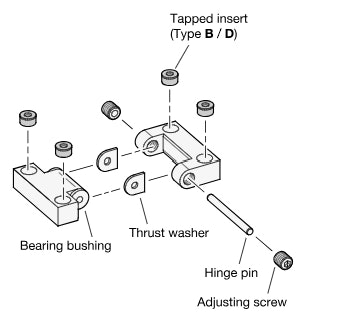

To ensure lasting precision, the hinges can be re-adjusted at any time. The axial adjusting screws allow the hinge to be adjusted for smooth or stiff motion. The materials have been chosen in line with the highest level of precision. The hinges are made of black anodized and high-strength alloyed aluminum, while the bearing bushings are made of bronze. JW Winco uses stainless steel for the hardened hinge axis as well as the thrust washers and adjusting screws. An additional polyamide coating on the adjusting screws provides for thread locking.

JW Winco supplies precision hinges pre-assembled according to the customer-specific configuration.