This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

For flexible packaging solutions at its finest, your best bet in Las Vegas is Matrix Packaging Machinery!

Matrix is demonstrating its lineup of vertical form fill seal (VFFS) solutions in Booth W-1122 at PACK EXPO 2025, September 29 – October 1, at the Las Vegas Convention Center.

Matrix, a ProMach product brand, is an expert in VFFS packaging equipment producing a variety of flexible bag styles, including pillow, gusseted, flat bottom, and modified doy. Matrix is also the North American master distributor for Pacraft and its rotary pre-made pouch solutions, as well as INVpack and its sachet and stickpack machine solutions. At PACK EXPO, Matrix will present live demonstrations of its flexible packaging solutions and show how its machinery seamlessly integrates with other ProMach equipment for complete, turnkey packaging lines.

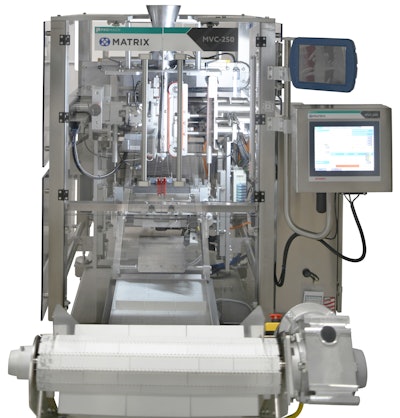

MVC-250

Taking the leading role in Las Vegas is the MVC-250, a one-of-a-kind continuous box-motion bagger with the latest high performance servo system for unprecedented precision motion control. The MVC-250 is a low-profile machine (62” height) that is designed to fit into tight spaces or areas with low ceilings, and can reach speeds up to 200 cycles per minute.

A hallmark of Matrix’s MVC Series is that the machines use a continuous-motion, high-speed jaw system where the film never stops. The jaw system seals and cuts the film and allows adjustable seal times for the cross seals to properly seal many types of films. This feature of the MVC Series allows users to achieve higher fill rates, making the MVC one of Matrix’s most advanced series of VFFS machines.

MVC-300

Another MVC Series machine in action at the show is the MVC-300, which includes enhanced remote connectivity for service, updates, and diagnostic capabilities without compromising facility firewalls. At the show, the MVC-300 will be integrated with the Cera2Seal system, which is a digital heating process from German-based Watttron (Booth SU-30066) that uses targeted and precise temperatures to seal a wide range of complex packaging styles and mono-materials used in sustainable packaging.

MVX-200

The MVX-200 is a flexible, compact VFFS that offers fast, easy changeovers for doypack applications. This robust machine can run both front and rear labelers, and can be outfitted with a reel elevator for quick splicing of the reel. Additionally, it comes with a hygienic stainless steel grill door for easy access.

Pacraft TT-8D-N

The Pacraft TT-8D-N pre-made pouch filler/sealer is engineered for a wide variety of packaging applications. It supports flat, stand-up, retort, and press-to-close pouch styles and seals up to 55 pouches per minute. Pouch sizes range from 4.72” to 10.23” (120 - 260mm) in width and 5.11” to 15.74” (130 – 400mm) in length. At the show, Matrix will be demonstrating the machine in a small footprint with Sealscope Technologies’ (Booth SL-12056) in-line solution for 100 percent seal inspection and monitoring of the sealing process.

INVpack INV SP6

The INV SP6 stickpack machine from INVpack is designed for medium to high production runs and is ideal for liquids, pasty, granulated, powders, and solids. This six-lane machine produces 420 stickpacks per minute, making it a perfect fit for powders, cosmetics, and other industries.

FL AutoSplicer Pro

The FL AutoSplicer Pro from FLtècnics, a ProMach product brand, is a stand-alone system that automates roll splicing for vertical and horizontal form fill seal machines. The system can easily integrate into existing machinery without requiring costly upgrades. The FL AutoSplicer Pro increases packaging machines’ productivity by up to 10 percent, significantly reduces material waste, enhances operator safety, and lowers labor costs.

Visit Booth W-1122 at PACK EXPO 2025 to see these flexible packaging solutions from Matrix, Pacraft, INVpack, and FLtècnics in action, and learn how they can help you increase productivity and meet your sustainability goals.