The stainless steel construction of the Paloma-D2 meets all current hygiene standards and regulations for food processing. Additionally, its high ingress protection class of IP 65 makes it ideal for deep frozen food applications. The new Gemini 3.0 Software allows simulation of new production processes and products on a virtual machine. A 3-D view enables operators to adjust and optimize pick-and-place patterns and other settings for each product in an intuitive manner. All individual parameters can be saved and recalled if required. The software and tool-free changeable form sets, like end-effectors, guarantee changeover time of less than five minutes.

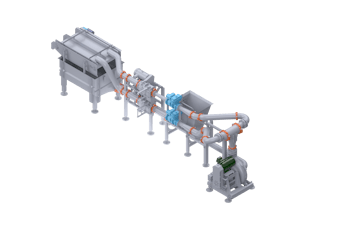

Washdown pick and place robot cell for carton, case, and tray packing

The Paloma-D2 robot is capable of picking and orienting 290 products per minute from the line into secondary packaging.

Aug 4, 2009

Companies in this video

Researched List: Engineering Services Firms

Looking for engineering services? Our curated list features 100+ companies specializing in civil, process, structural, and electrical engineering. Many also offer construction, design, and architecture services. Download to access company names, markets served, key services, contact information, and more!

Download Now

Construction strategies for volatile F&B markets

See how leading manufacturers are fast-tracking projects despite economic uncertainty. Get proven tactics for overcoming tariffs, labor shortages, and rising costs.

Read More